Mixers for baked products

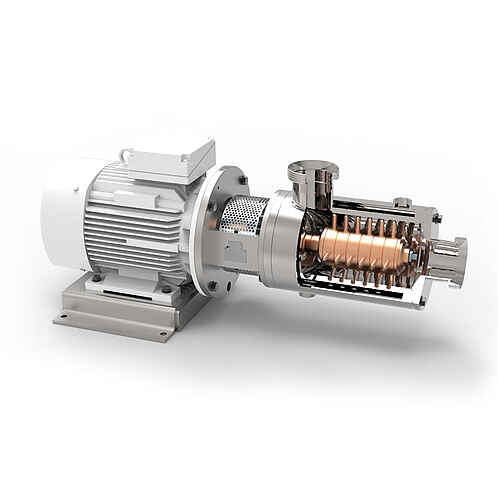

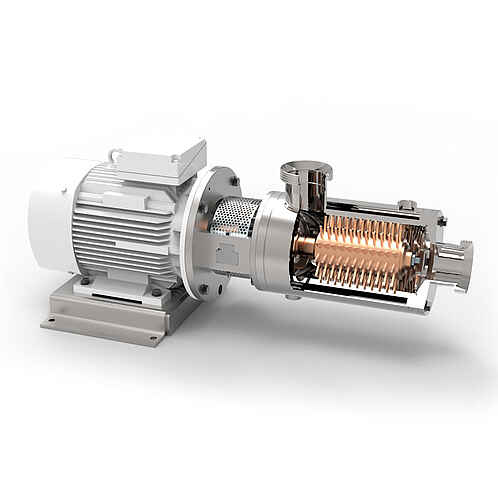

When mixing baked products, the most important aspects are a hygienic processing and a mixing process that treats the product gently. For this continuous process, there is a sterile model of INDAG dynamic inline mixer offering a minimal dead zone. The capability for standard CIP (cleaning-in-place) and complete drainage enables a safe production process.

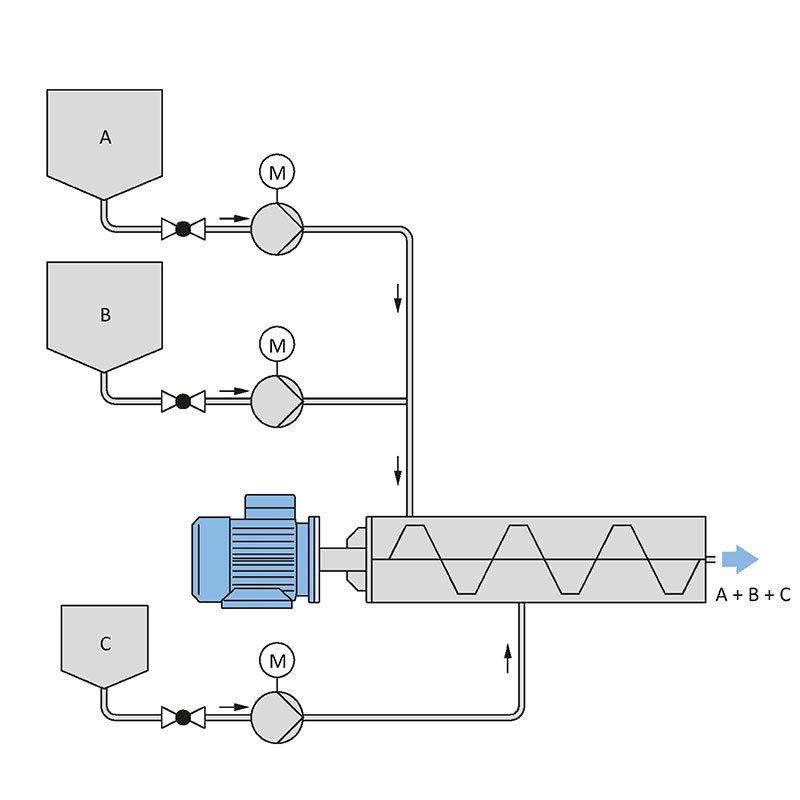

Liquid + Liquid

INDAG mixers are very well suited for mixing liquids. It is possible to mix two media, but a variety of liquids can also be mixed together. By liquids we mean pumpable media. Depending on the mixing task, the INDAG mixer types DLM/M, DLM/P, DLM/S and DLM/H are suitable for mixing liquids for baked goods. .

Application examples

Dynamic Inline Mixer:

- Fat filling + flavouring

- Fat filling + colouring

- Fat filling + chocolate, coffee paste, nut pulp

- Fat filling + liqueur, syrup

- Fondant + colour/flavouring

- Fondant + additives

- Melted sugar mass + chocolate fat mass, flavouring

- Chocolate coating

- Milk filling + colour/flavour

- Cream filling + rum sultana paste

- Dough + colouring

Application examples

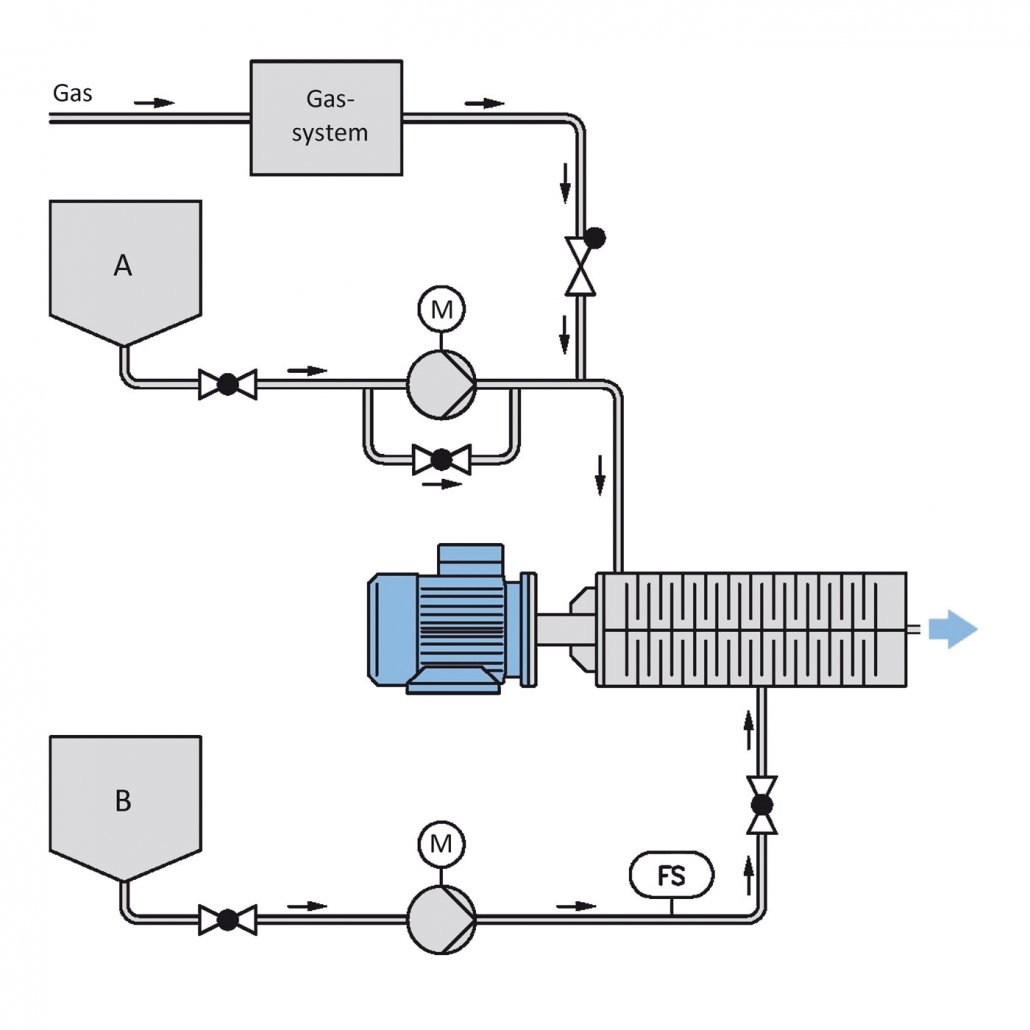

Intensive Inline Mixer:

- Sponge mixture + compressed air

- Sponge mixture/quark mixture + air

- Aerate/foam fillings

- Cream + nitrogen

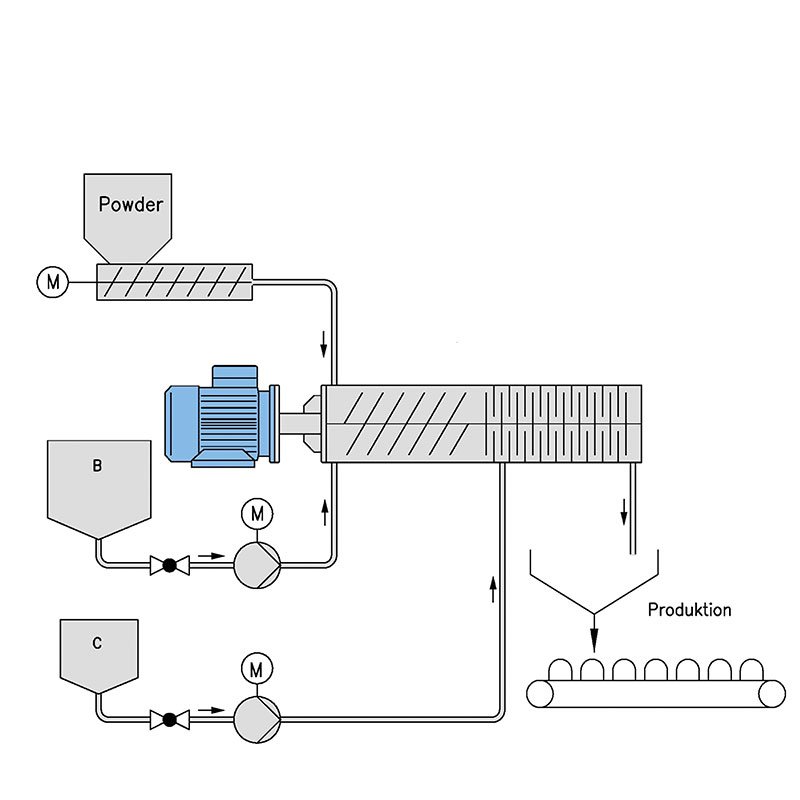

Liquid + Solids

The term 'solids' covers all non-pumpable media. These can be powders, granulates, or large particles. In order to continuously mix defined amounts of these into a liquid, we use our solid-liquid mixer type DLM / FS.

Application examples

Solid-Liquid Inline Mixer:

- Filling + cerials, nuts, chocolate pieces

- Fondant + cerials, nuts, chocolate pieces

- Dough + cerials, nuts, chocolate pieces

- Water + flour

+

+

+

+

![INDAG DLM/FS - Solid-Liquid Inline Mixer [Translate to English:] INDAG DLM/FS - Fest-Flüssig Inline Mischer](/fileadmin/_processed_/f/e/csm_indag-dlm-fs-food-2021_aff8d6a87e.jpg)