DLM/FS

Solid-Liquid Inline Mixer

Continuous homogeneous mixing of solids with liquids

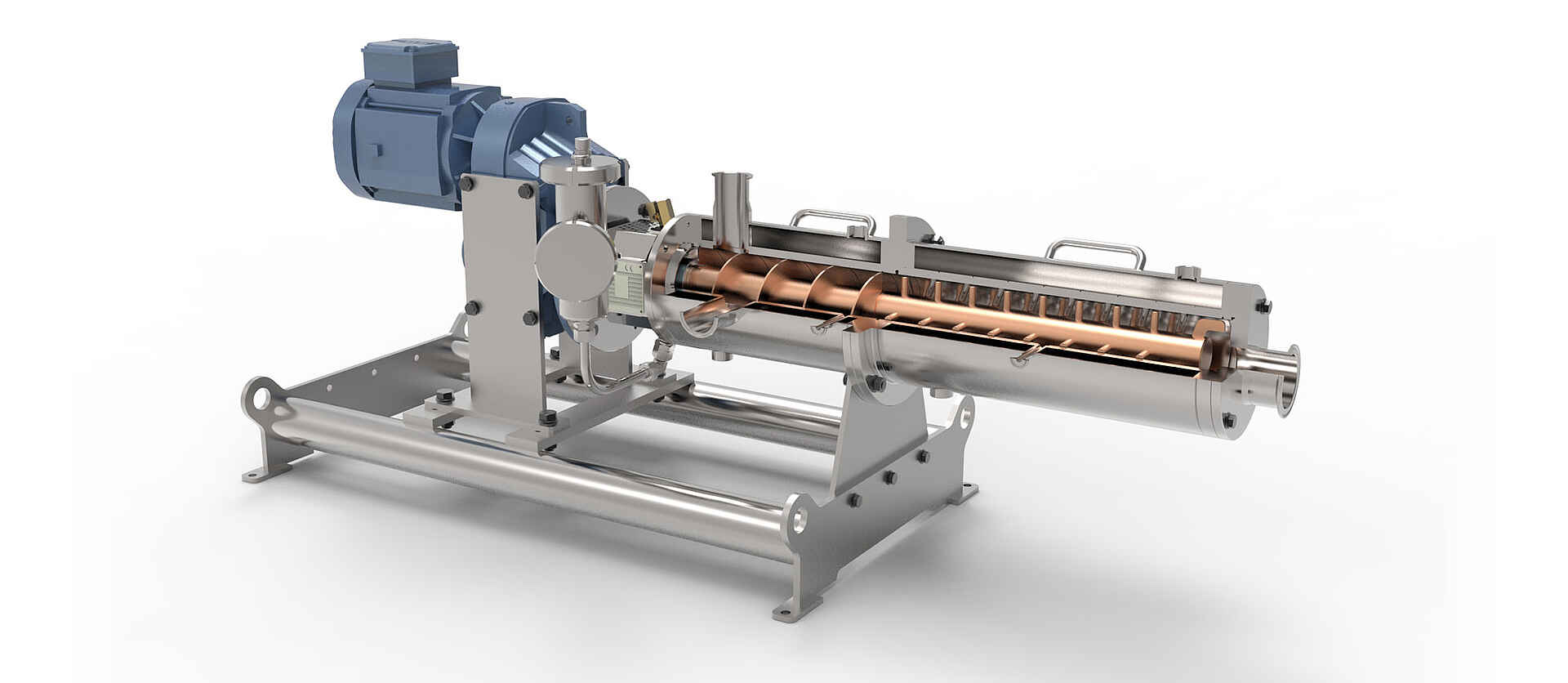

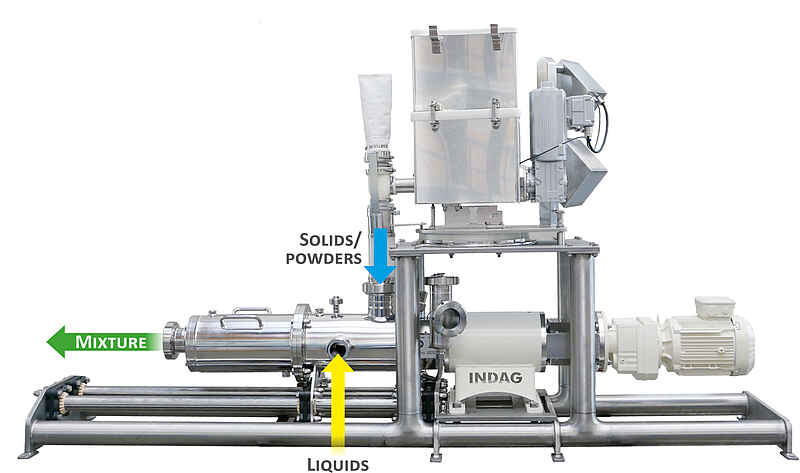

The INDAG Solid-Liquid Inline Mixer type DLM/FS is used for the continuous mixing of liquids with solids. The solids can be up to 20 mm in size (sphere diameter) or in powder form. The liquid component is usually the larger proportion by weight. Depending on the geometry of the mixing elements, the solids can be mixed very gently or with an increased shear rate. This ensures that powders are finely dispersed and that larger solids or granules are not damaged during mixing. Solids can also be mixed into foams without damaging them. All our different mixing elements (paddles, pins, or stars) are available for the DLM/FS to cover a wide range of mixing applications.

Advantages of the DLM/FS:

- Product temperature increase of less than 1 °C

- Gentle mixing of shear-sensitive products

- Excellent homogeneous mixing results, even when mixing in minute quantities (0.1%)

- Very good self-cleaning during CIP (Clean-in-Place) cleaning.

Application examples for the DLM/FS:

- Adhesive + powder mixture

- Silicone + fillers

- Oils + powders, solids

- Polyethylene + pigment powder

- Polymers + fillers

- Polymer + pigment powder

- Polyurethanes + fillers

- Water + zinc sulfide dust

Technology of DLM/FS

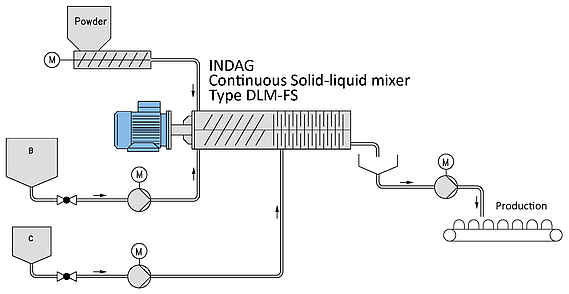

The INDAG Solid-liquid Inline Mixer type DLM/FS consists of a feeding zone and a mixing zone. The liquid and solids are fed into the feeding zone, from where they are transferred to the mixing zone by means of a screw conveyor. The mixing zone contains mixing elements in the rotor as well as the stator. Thanks to the special arrangement of mixing elements and feeding zone, the ingress of gases into the product is limited to a minimum. At the discharge end, the mixed product is fed virtually pressure free to the next processing stage. The mixed product either enters a buffer container or is fed to a pump. Both stator and rotor are available as heated versions (double-walled). For machines with frequent manual cleaning cycles, and because of the easier maintenance, we recommend a machine frame with the mixer housing mounted on the „Easy clean“ carriage. The DLM/FS is perfectly suited for CIP cleaning. Optionally, every mixer can be fitted with a double acting mechanical seal or a stuffing box seal. The DLM/FS comes in various sizes, and is suitable for use in explosion-hazarded zones G2, D21, and D22 (ATEX). We offer rental machines for tests on the customer’s site or at INDAG.

Positioning

horizontal

Pressure levels

6 bar; depending on the material‘s viscosity, the mixer itself generates a max. pressure of 0.5 bar at the discharge end.

Materials

1.4404 (AISI 316L), higher grades on request

Seals

Double acting mechanical seal; stuffing box seal

Connections

Dairy connections to DIN 11851, DIN 11864, Tri Clamp, SMS or others

Rotational speed

100 rpm to 300 rpm

Capacities

100 l/h to 7,000 l/h

Temperatures

0 °C to 300 °C

Viskosities

1 mPas up to 10.000.000 mPas

Mixer sizes and capacities of DLM/FS

| Type DLM/FS | Unit | 2 | 3 | 4 | 5 |

| capacity* | l/h | 100 - 800 | 500 - 2.000 | 1.000 - 3.600 | 1.500 - 7.000 |

| connection solids* | mm | 80 | 100 | 125 | 150 |

| power* | kW | 1,5 - 2,2 | 2,2 - 4 | 4 - 7,5 | 5,5- 11 |

| rotational speed* | 1/min | 150 - 300 | 150 - 300 | 100 - 200 | 100 - 200 |

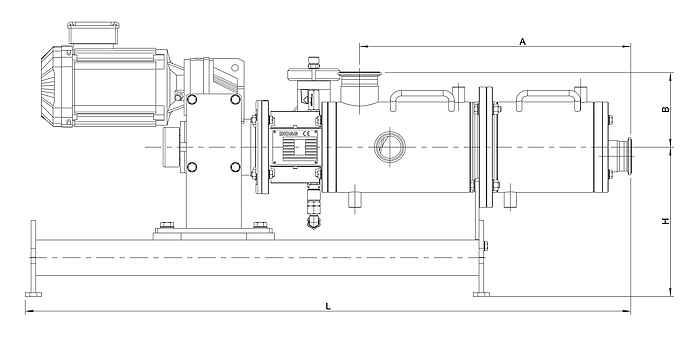

Dimension drawing of DLM/FS

| Type | Unit | A | B | H* | L* |

| DLM/FS-206 KB | mm | 565 | 145 | 320 | 1300 |

| DLM/FS-306 KB | mm | 605 | 185 | 380 | 1620 |

| DLM/FS-408 KB | mm | 675 | 215 | 420 | 1860 |

| DLM/FS-508 KB | mm | 880 | 254 | 450 | 2100 |