DLM/S

Intensive Inline Mixer

Intensive mixing with star mixing elements

for challenging mixing applications

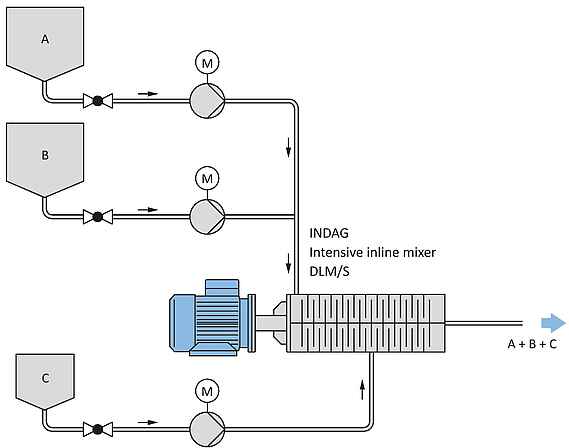

INDAG Intensive Inline Mixer type DLM/S is used for effective mixing, emulsifying, dispersing and aerating of fluids, solids and gases. Examples of applications are: mixing of egg yolk, oil and vinegar solution to create a premixture for mayonnaise or dressing. Another example is aeration of marshmallows. In this case egg white, a sugar syrup and air is mixed to achieve a fine-pore foam. For aeration of products INDAG supplies the suitable gas dosing unit. The DLM/S mixer is also used to homogenously mix a sugar solution with an aroma. Applications can also be found in the production of process cheese. Here, the cheese is effectively boiled with steam.

Advantages of DLM/S

- Very good self-cleaning during CIP-cleaning

- No pressure loss

- No blockage

- Very homogenous mixing result even for extreme concentration ratios

- Efficient introduction of mixing energy

- Variable mixing energy through speed change via frequency converter

- Execution with double jacket and further connections possible

- Suitable for highest viscosity

Technology of DLM/S

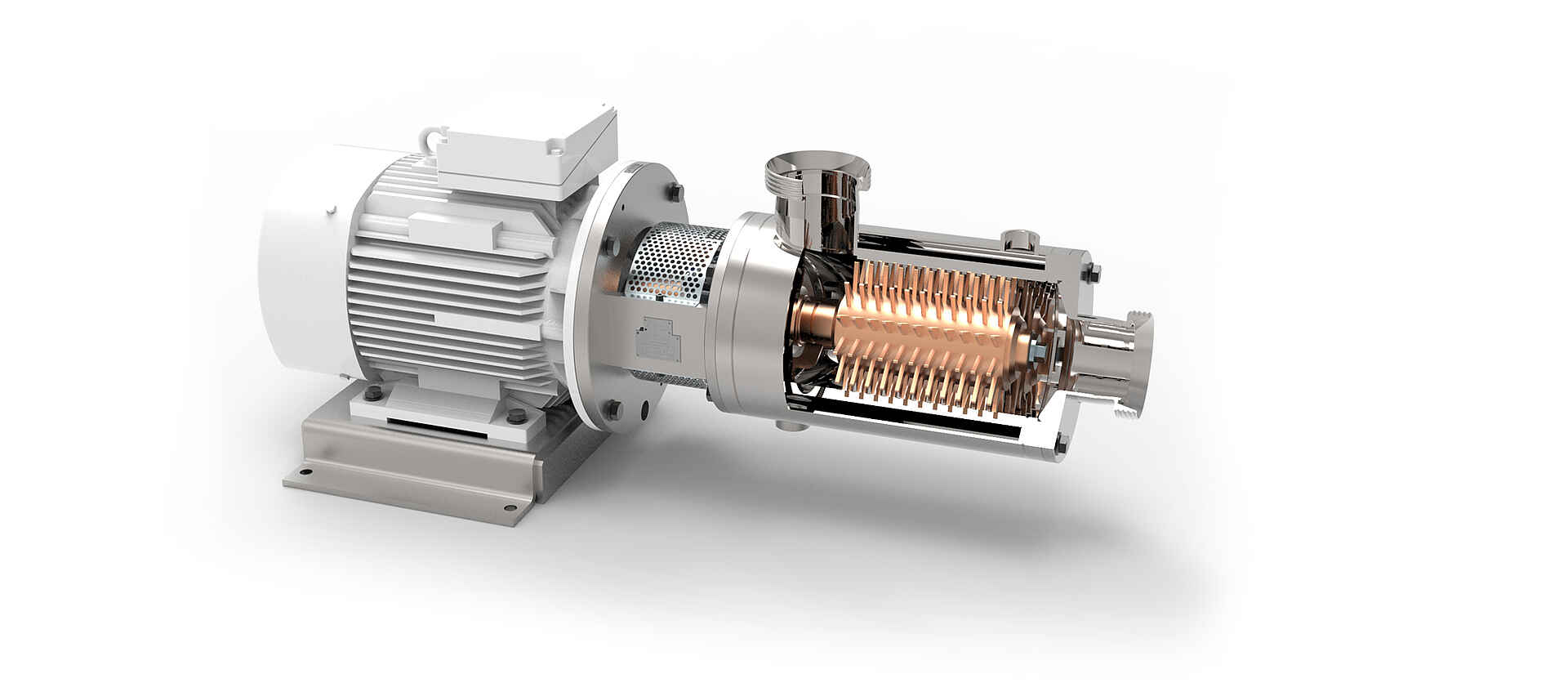

INDAG mixer type DLM/S consists of patented star shape mixing elements on rotor and in stator (mixer casing). Star shape design is extremely robust to allow mixing of highly viscous products (> 10,000,000 mPas). Mixing energy is introduced efficiently into product. Rotor and stator can be designed to be cooled or heated. The DLM/S is offered in compact design (KB) and in bearing block design (LB). In the compact design, the rotor is mounted by the output shaft of the motor. In the bearing block design, the rotor is mounted by its own bearing block. With a separate bearing block, longer rotors and thus larger mixing volumes can be realized. Furthermore, this design is also suitable for mixing under high pressure or high temperature. The type of rotor seal is selected to suit each application. For the supply of the double-acting mechanical seal INDAG offers the suitable barrier fluid system.

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar

Materials

1.4404 (AISI 316 L) or higher quality on request

Seals

Single acting mechanical seal; double acting mechanical seal; even in aseptic execution

Connections

Dairy connections according to DIN 11851, DIN 11864, Tri Clamp, SMS and various others on request

Rotational speed

200 rpm to 3.600 rpm

Capacities

50 l/h to 120,000 l/h

Temperatures

0 °C to 250 °C

Viskosities

1 mPas to 10,000,000 mPas

Mixer sizes and capacities of DLM/S

| Type DLM/S | Unit | 1 | 2 | 3 | 4 | 5 | 6 |

| capacity* | l/h | 100-2.000 | 200-5.000 | 500-10.000 | 1.000-20.000 | 3.000-60.000 | 6.000-120.000 |

| connection | DN | 25-50 | 32-50 | 40-80 | 65-100 | 80-125 | 80-150 |

| optional | ASME | 1-23” | 1.5-2” | 13/4-3” | 2.5-4” | 3-5” | 3-6” |

| power* | kW | 0,55-4 | 1,5-7,5 | 2,2-15 | 4-30 | 5,5-55 | 11-90 |

| rotational speed* | 1/min | 200-3.600 | 200-3.600 | 200-1.800 | 200-1.800 | 200-1.500 | 800-1.500 |

| mixing stages KB | DLM/S-105 KB | DLM/S-205 KB | DLM/S-305 KB | DLM/S-405 KB | DLM/S-505 KB | DLM/S-605 KB | |

| mixing stages LB | DLM/S-110 LB | DLM/S-215 LB | DLM/S-320 LB | DLM/S-420 LB | DLM/S-520 LB | DLM/S-620 LB |

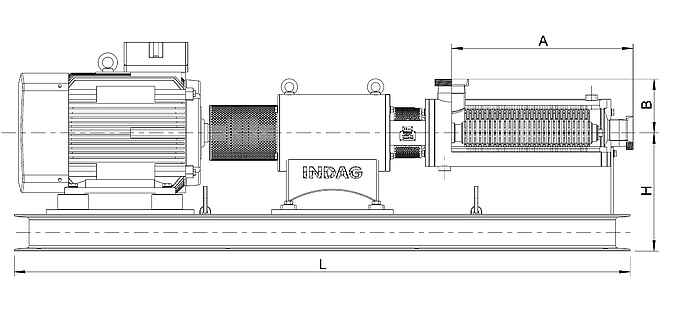

Dimension drawing of DLM/S with bearing block (LB)

| Type | Unit | A | B | H* | L* |

| DLM/S-110 LB | mm | 382 | 140 | 260 | 1400 |

| DLM/S-215 LB | mm | 498 | 155 | 312 | 1700 |

| DLM/S-320 LB | mm | 509 | 175 | 385 | 2000 |

| DLM/S-420 LB | mm | 542 | 205 | 460 | 2100 |

| DLM/S-520 LB | mm | 575 | 244 | 460 | 2200 |

| DLM/S-620 LB | mm | 608 | 294 | 510 | 2500 |

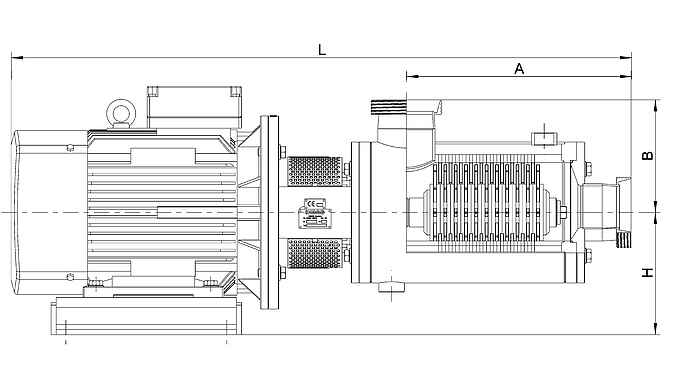

Dimension drawing of DLM/S compact version (KB)

| Type | Unit | A | B | H* | L* |

| DLM/S-105 KB | mm | 233 | 140 | 150 | 655 |

| DLM/S-205 KB | mm | 258 | 155 | 158 | 773 |

| DLM/S-305 KB | mm | 269 | 175 | 190 | 883 |

| DLM/S-405 KB | mm | 302 | 205 | 190 | 945 |

| DLM/S-505 KB | mm | 335 | 244 | 218 | 1004 |

| DLM/S-605 KB | mm | 369 | 294 | 242 | 1210 |