Mixers for chemistry

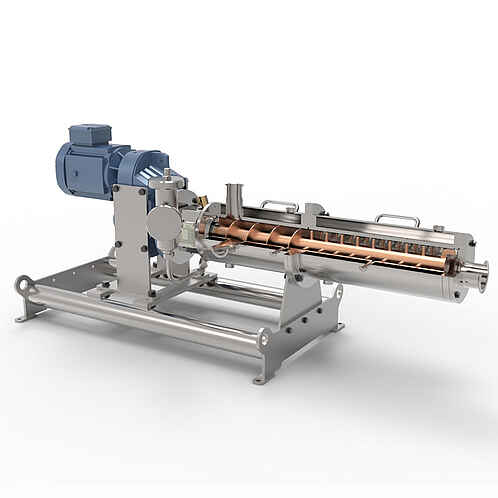

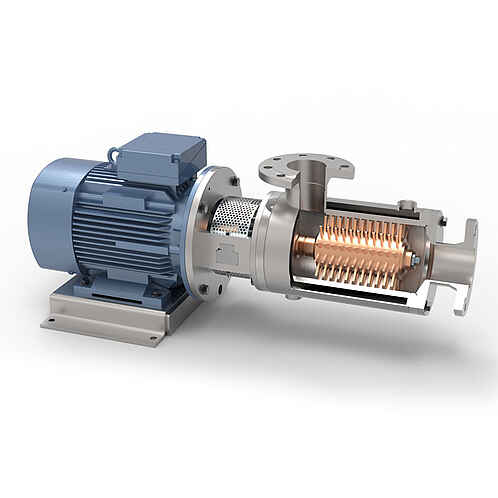

When mixing chemicals, clean processing, suitable materials and an adapted mixing process are essential. Especially with corrosive or abrasive media, the right material of the mixer as well as the suitable coating play a major role. INDAG dynamic inline mixers offer a stable and low dead space design for this continuous process. INDAG mixers are also manufactured for explosive areas and substances (ATEX). INDAG has cooperations with some German universities where research is done with INDAG mixers with different medium and high viscosity products. This enables us to continuously optimise our mixers.

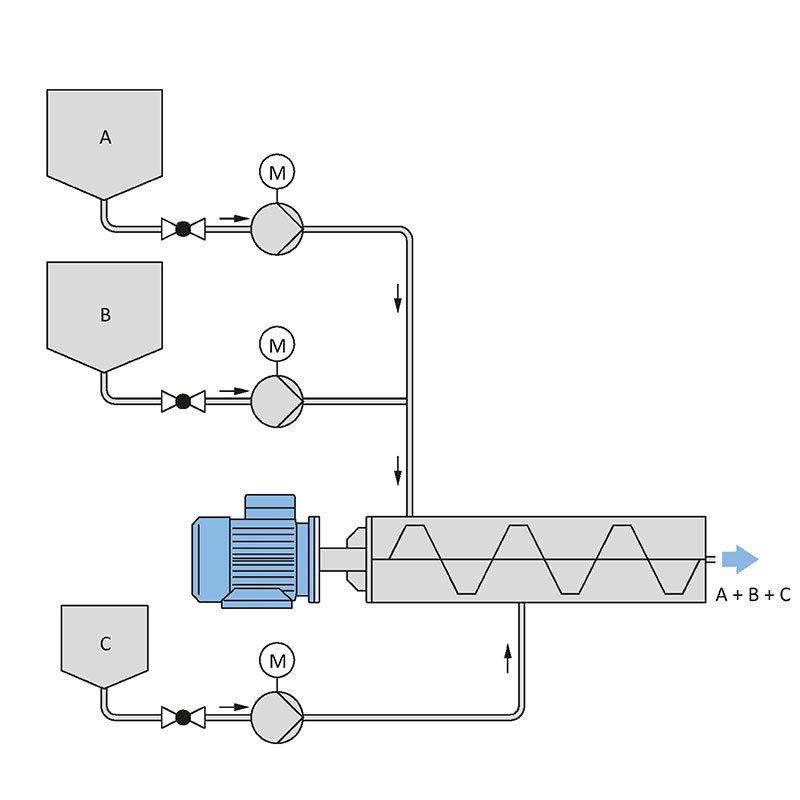

Liquid + Liquid

INDAG mixers are very well suited for mixing liquids. It is possible to mix two media, but a variety of liquids can also be mixed together. By liquids we mean pumpable media. Depending on the mixing task, the INDAG mixer types DLM/M, DLM/P, DLM/S and DLM/H are suitable for mixing liquids for chemical products.

Application examples

Gentle Inline Mixer:

- Antifoam production

- Antifoam + methanol

- Water-based paint+ pigments dissolved in water (2%)

- LAO + NaOH

- Latex + chemicals

- Latex foam + gelling agent

- Latex compound + air

- solvent, hot water + solvent + wax premix

- Raw glycerine + sodium hydroxide solution

- Sulphuric acid + water

- Soap + hydrochloric acid

- suspension (lead sludge agglomerates, activated carbon)

- synthetic latex

- various pesticides

- water + coolant concentrate

- water + FeCI3 or AI2SO4

- glycerine + water

- Glycerine, Methanol + HCL 35%

- Vegetable oil + caustic soda

- NaOH + crude glycerol

- PVAC latex

Application examples

Intensive Inline Mixer:

- Ammonium nitrite high viscosity + additives

- Antifoam production

- antifoam+ methanol

- Aramid fibres (refining)

- BaSO4 slurry + aqueous solution

- BaSO4 slurry + additives

- Gasoline Resin

- BHT + biodiesel

- Biodiesel + HCl

- Biodiesel + Additive Infineum R 408

- Biodiesel + citric acid additive for catalyst neutralisation

- Bitumen + Adhesive

- Bitumen + Sasobit (wax)

- Bitumen Rubber compound

- Butane + Butane/Lye/Water

- Demi-water + aromatic phenols

- Demi-water + palm oil

- Ester + Viscose

- Liquid soap concentrate + water

- Liquid detergent + brightener & other components

- Dishwashing liquid + Paint

- Urea glue, urea solution + wax emulsion

- Hard bitumen + Soft bitumen

- Resin + Hardener, Accelerator

- Household cleaner + additives

- Adhesives + Isocyanate

- Adhesives + additives, crosslinkers

- Lecithin, water + ammonia, hydrogen peroxide solution

- Lecithin sludge, vegetable oil + hydrogen peroxide

- Solvent waste (e.g. toluene, methanol) + glycerine

- Melamine resin + pentane

- Molasses + saline solution + water

- Lactic acid + alk. high viscosity medium

- NMMNO spinning solution + additives

- Oil + paint

- Oil/grease + wash water

- Palm oil + water

- Paraffin with thickeners

- Vegetable oil + methanol, glycerine

- Phenolic resin + water

- Phospholopase + lecithin, water, ammonia, hydrogen peroxide solution

- Polyetheremide + dichloromethane

- Polyetheremide in dichloromethane + water with surfactant

- Polymer + coupler

- Polymer melt + crosslinker

- Detergent base + surfactant / cleaner

- Detergent + Additive

- Crude oil, water slime in extraction

- Residue solution (50% isocyanate) + bitumen

- Salt solution + oxygen

- Lubricating oils + additives

- Sodium lauryl ether sulphate concentrate + water

- Sunflower oil + dissolved TriSyl

- Tall resin + turpentine

- animal fat + hot water (10%) or citric acid (1-2%)

- vacuum-distilled asphalt "Blown asphalt"

- various pesticides

- Diluted liquid soap + Various additives

- Vestinol + ASEP

- Vinyl acetate, NMA + water, ethylene sulphonate

- Viscose (solution) + ester

- Viscose solution + dissolved colour

- Water (50 %) + Fat (25 %) + Protein & Starch (25 %)

Application examples

Inline Homogenizer:

- Bentonite suspension + waste water

- Biodiesel + Acid Process Water

- Biodiesel + Water

- CPO + Acid

- Miscella degumming

- Vegetable oil + phosphoric acid

- Vegetable oil + citric acid

- SLES dilution

- Soybean / rapeseed oil + phosphoric acid

- Water + flavouring, old dextrin (make emulsion)

- Water + emulsifier, stabiliser

- Water + oil

- Water + wax

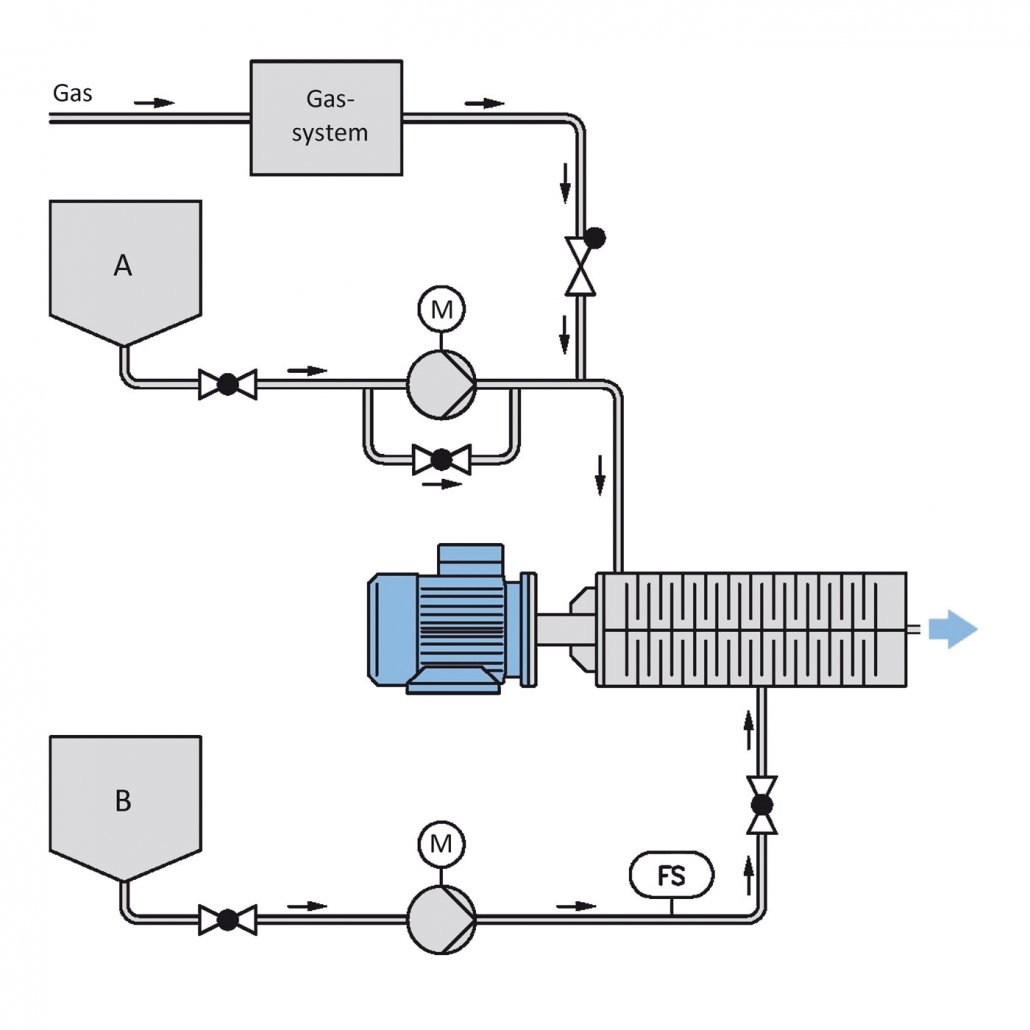

Application examples

Intensive Inline Mixer:

- Polybutadiene + steam

- Polymer solution + steam

- Foam detergent slurry

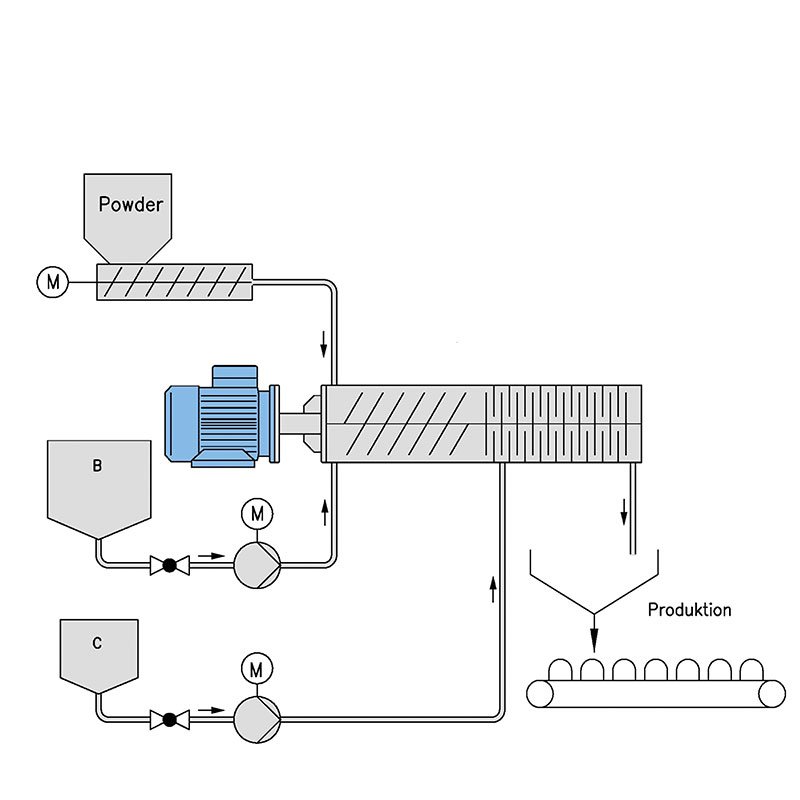

Liquid + Solids

The term 'solids' covers all non-pumpable media. These can be powders, granulates, or large particles. In order to continuously mix defined amounts of these into a liquid, we use our solid-liquid mixer type DLM / FS.

Application examples

Solid-Liquid Inline Mixer:

- Adhesive + powder mixture

- Silicone + fillers

- Oils + powder, solids

- Polyethylene + pigment powder

- Polymers + fillers

- Polymers + pigment powder

- Polyurethane + fillers

- Water + zinc sulphide dust

+

+

+

+

+

+