DLM/M ECO

Gentle Inline Mixer

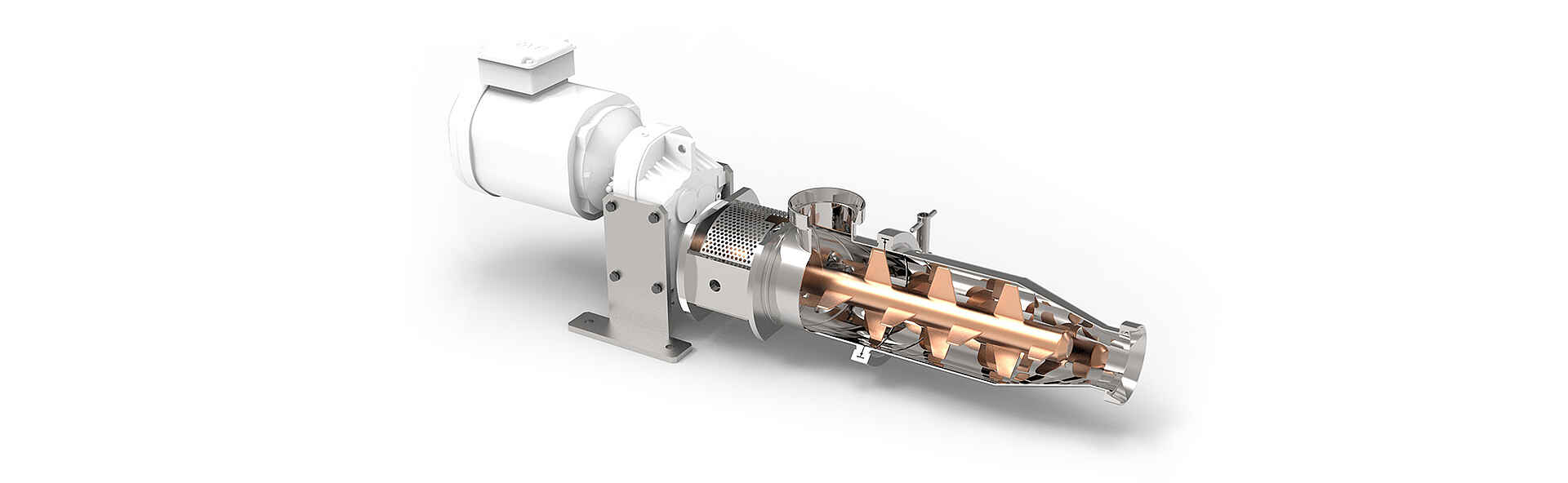

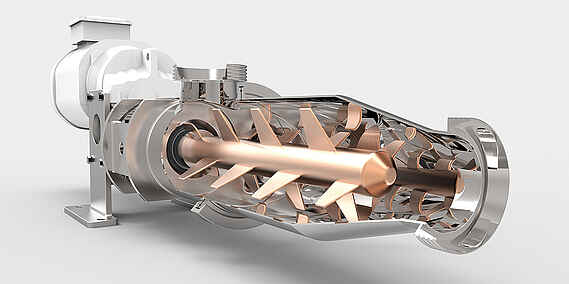

Gentle mixing with paddle mixing elements

for shear sensitive products

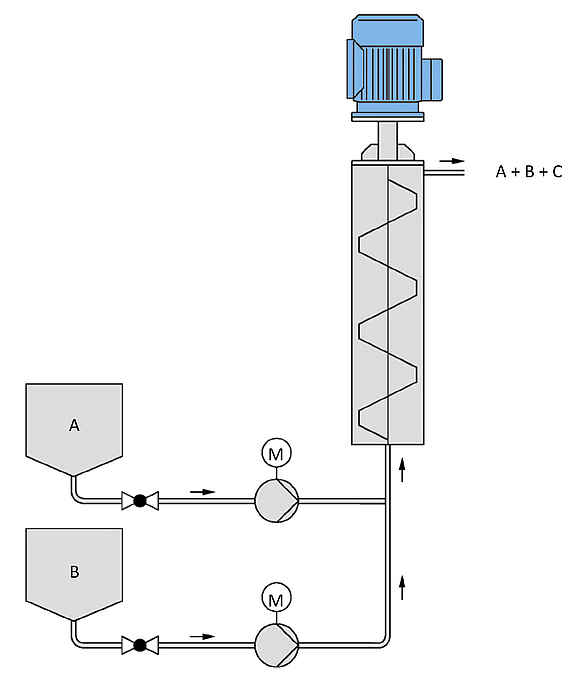

The INDAG Gentle Inline Mixer, type DLM/M ECO, is used for gentle and homogeneous mixing of mostly shear-sensitive products. For example, fruit concentrate is mixed into yoghurt or quark and chocolate into ice cream. Different ingredients can also be gently mixed into foams. For a chocolate mousse, chocolate is folded into an egg white foam without destroying the delicate foam. Caustic soda is mixed into a vegetable oil to neutralise it or a flavouring is mixed into a fat mass.

Advantages of DLM/M ECO

- Very good self-cleaning during CIP-cleaning

- No pressure loss

- No blockage entwining (clog) free

- Very homogenous mixing result

- Variable mixing energy through speed change via frequency converter

- Attractive pricing due to fabrication in higher quantities

Technology of DLM/M ECO

The INDAG Gentle Inline Mixer type DLM/M ECO is available in addition to the standard INDAG DLM/M version. As the name ECO (Economic) already indicates, this mixer can be offered at attractive prices due to production in larger quantities. In order to achieve larger quantities, however, the DLM/M ECO is not freely configurable.

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar

Materials

1.4404 (AISI 316L)

Seals

Single acting mechanical seal; double acting mechanical seal

Connections

Dairy connections according to DIN 11851, DIN 11864,

Tri Clamp, SMS and various others on request

Rotational speed

100 rpm to 1,800 rpm

Capacities

100 l/h to 13,000 l/h

Temperatures

0 °C to 150 °C

Viskosities

1 mPas to 50,000 mPas

Mixer sizes and capacities of DLM/M ECO

| Type DLM/M ECO | unit | 1 | 2 | 3 |

| capacity* | l/h | 100 - 2.000 | 200-5.000 | 500-13.000 |

| connection | DN | 40 | 50 | 80 |

| optional | ASME | 1,5" | 2" | 3" |

| optional | SMS | 38 | 51 | 76 |

| power | kW | 0,55-1,1 | 1,1-2,2 | 2,2-3 |

| rotational speed | 1/min | 100-1.800 | 100-1.800 | 100-1.800 |

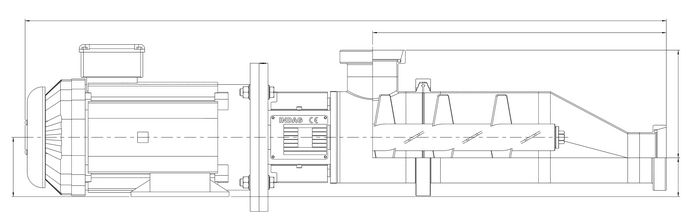

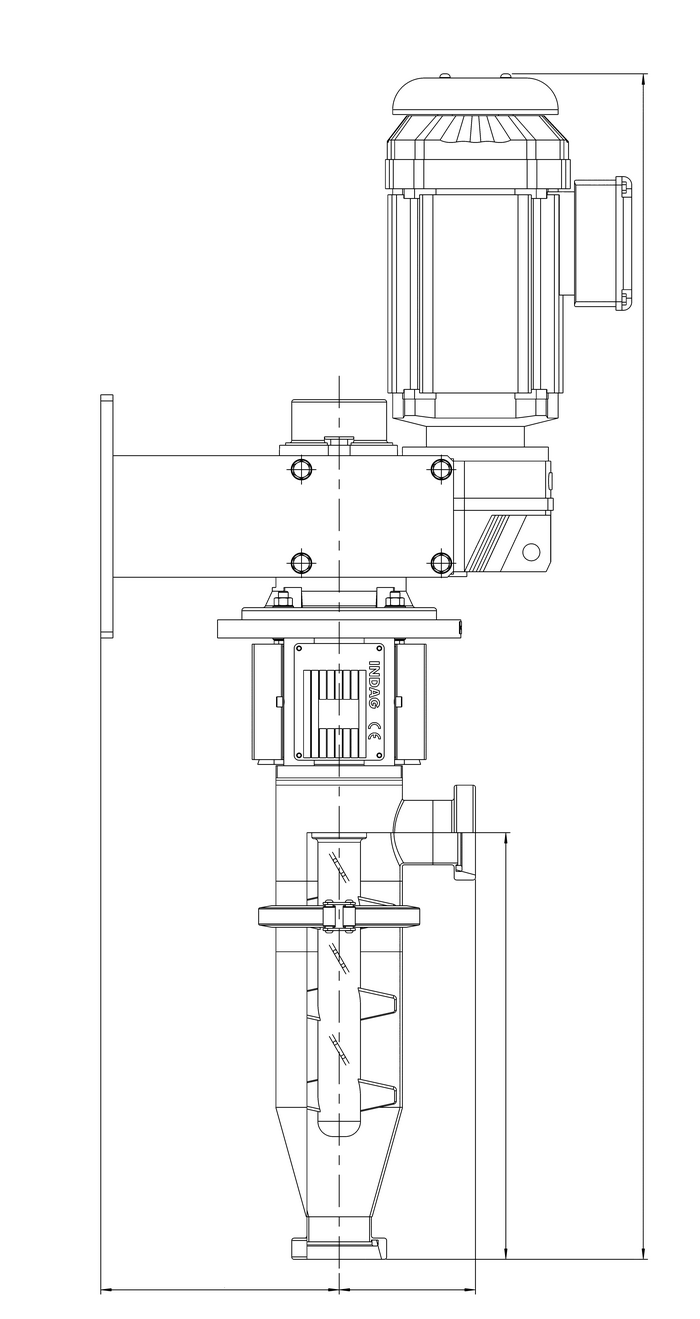

Dimension drawing of DLM/M ECO HY VE KB

| Type | unit | A | B | H* | L* |

| DLM/M-1 | mm | 306 | 85 | 104 | 820 |

| DLM/M-2 | mm | 346 | 104 | 116 | 880 |

| DLM/M-3 | mm | 462 | 126 | 133 | 1133 |

Dimension drawing of DLM/M ECO HY HO KB

| Type | unit | A | B | H* | L* |

| DLM/M-2 | mm | 396 | 138 | 75 | 915 |

| DLM/M-3 | mm | 494 | 182 | 66 | 1079 |