DLM/M Gentle Inline Mixer

Gentle mixing with paddle mixing elements

for shear sensitive products

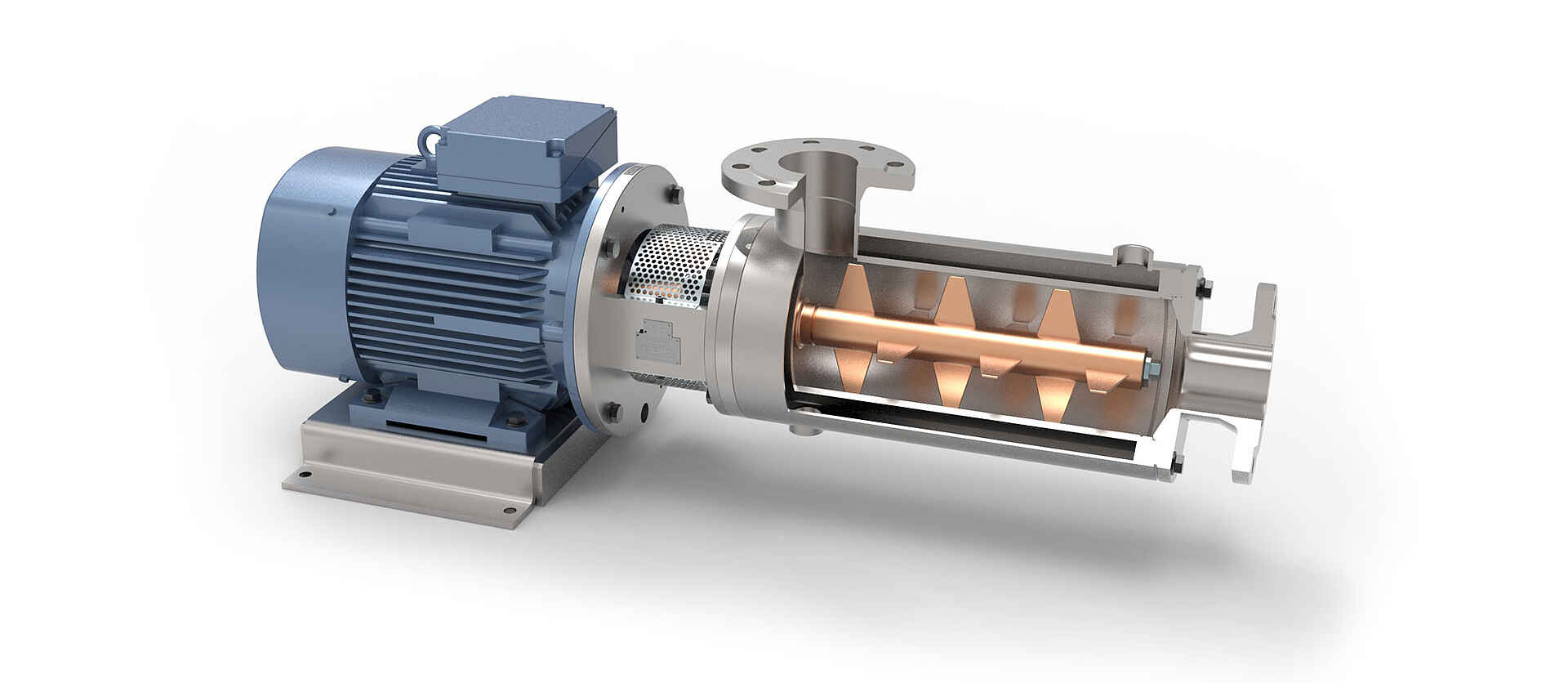

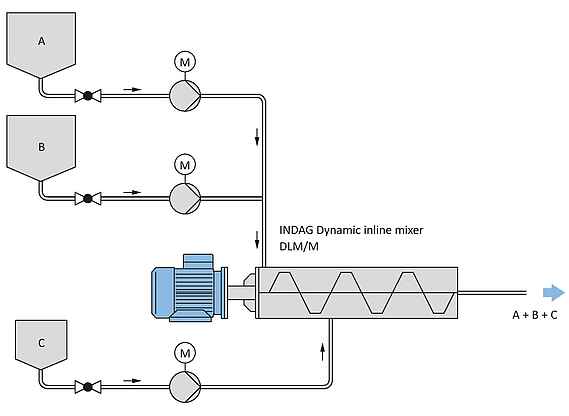

INDAG Gentle Inline Mixer type DLM/M is used to mix homogeneously a diversity of liquids. Even shear sensitive liquids or liquids with high solid content can be mixed. Only DLM/M rotor is equipped with mixing elements. Stator is without mixing elements. Therefore even fibrous particles will not lead to blockage of mixer. Additives can be mixed gently into foams without affecting the foam quality.

Advantages of DLM/M

- No pressure loss

- No blockage entwining (clog) free

- Very homogenous mixing result

- Mixing energy can be changed variable and adapted to product or capacity changes

- Applicable at high pressures and high temperatures

- Very good self-cleaning during CIP-cleaning

Examples of mixing tasks of DLM/M

- Antifoam + methanol

- Water-based paint + pigments dissolved in water (2%)

- Latex + chemicals

- Sulphuric acid + water

- Soap + hydrochloric acid

- Suspension (lead sludge agglomerates, activated carbon)

- Water + coolant concentrate

- Glycerine, methanol + HCL 35%

- Vegetable oil + caustic soda

- Various plant protection products

- NaOH + crude glycerine

- PVAC latex

Technology of DLM/M

INDAG Gentle Inline Mixer type DLM/M has only mixing elements on rotor and no mixing elements in stator (mixer casing). Rotor can be equipped with mixing elements of different geometry. Geometry depends on products to be mixed. The DLM/M is offered in compact design (KB) and in bearing block design (LB). In the compact design, the rotor is mounted by the output shaft of the motor. In the bearing block design, the rotor is mounted by its own bearing block. With a separate bearing block, longer rotors and thus larger mixing volumes can be realized. Furthermore, this design is also suitable for mixing under high pressure or high temperature. The type of rotor seal is selected to suit each application. For the supply of the double acting mechanical seal INDAG offers the suitable barrier fluid system. INDAG mixers are designed likewise for explosive areas and substances (ATEX).

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 100 bar

Materials

1.4404 (AISI 316L), 1.4462 (AISI 318), PVDF, PTFE, Teflon coated, Tantal coated

Seals

Single acting mechanical seal; double acting mechanical seal; stuffing box seal, magnetic coupling

Connections

EN, DIN, ANSI flange and various others on request

Rotational Speed

100 rpm to 1,800 rpm

Capacities

50 l/h to 120,000 l/h

Temperatures

0 °C to 300 °C

Viskosities

1 mPas to 1,000,000 mPas

Mixer sizes and capacities of DLM/M

| Type DLM/M | UNIT | 1 | 2 | 3 | 4 | 5 | 6 |

| capacity* | l/h | 100-2.000 | 200-5.000 | 500-10.000 | 1.000-20.000 | 3.000-60.000 | 6.000-120.000 |

| connection | DN | 40-80 | 50 -100 | 65-150 | 80 -200 | 100-250 | 125-300 |

| optional | ASME | 1,5” -3” | 2”-4” | 2,5”-6” | 3”-8” | 4”-10” | 5”-12” |

| power | kW | 0,75-2,2 | 1,1-3 | 1,5-4 | 2,2-7,5 | 5,5-18,5 | 7,5-30 |

| rotational speed | 1/min | 100-1.800 | 100-1.800 | 100-1.800 | 100-1.800 | 100-1.000 | 100-1.000 |

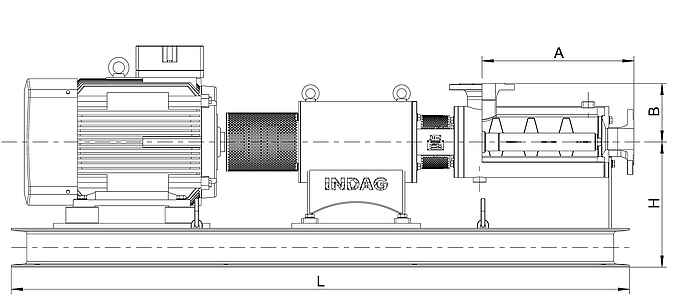

Dimension drawing of DLM/M with bearing block (LB)

| Type | Unit | A | B | H* | L* |

| DLM/M-1 LB | mm | 340 | 138 | 250 | 1500 |

| DLM/M-2 LB | mm | 376 | 165 | 312 | 1700 |

| DLM/M-3 LB | mm | 467 | 180 | 385 | 1900 |

| DLM/M-4 LB | mm | 569 | 210 | 460 | 2200 |

| DLM/M-5 LB | mm | 652 | 242 | 460 | 2500 |

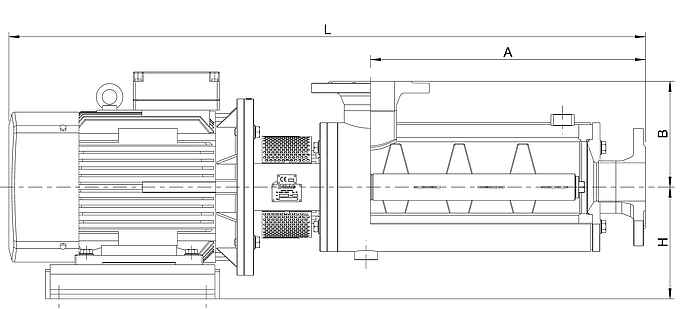

Dimension drawing of DLM/M compact version (KB)

| Type | Unit | A | B | H* | L* |

| DLM/M-1 KB | mm | 340 | 138 | 158 | 892 |

| DLM/M-2 KB | mm | 376 | 165 | 170 | 998 |

| DLM/M-3 KB | mm | 467 | 180 | 190 | 1081 |

| DLM/M-4 KB | mm | 569 | 210 | 190 | 1230 |

| DLM/M-5 KB | mm | 652 | 242 | 218 | 1390 |