Mixers for confectionery

When mixing confectionery, the most important thing is hygienic processing and a mixing process that is gentle on the product. INDAG dynamic inline mixers offer a sterile and low dead space design for this continuous process. Standard CIP (clean-in-place) cleaning and complete drainage allow a safe production process.

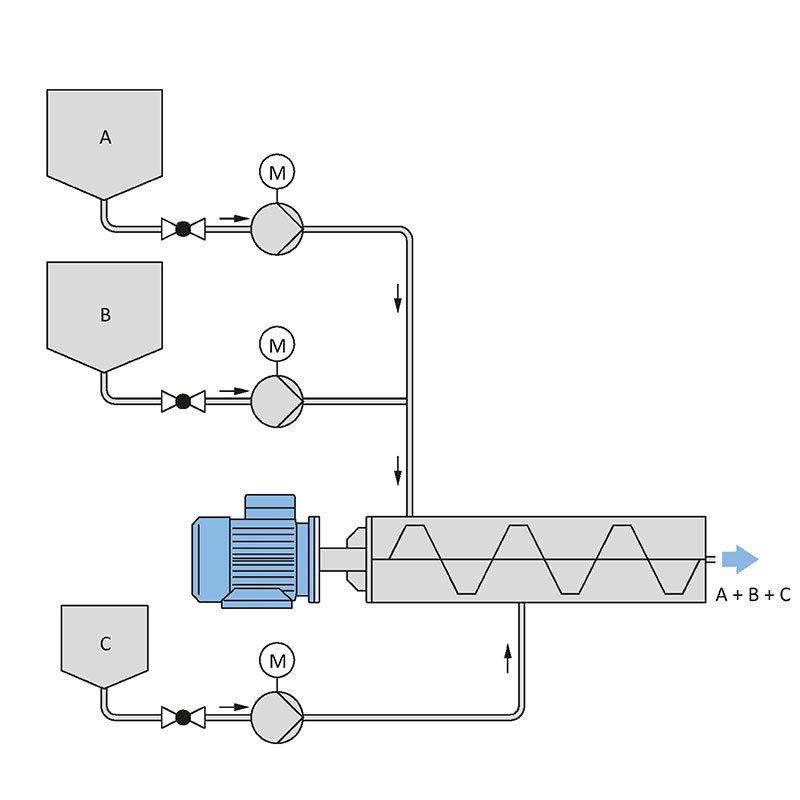

Liquid + Liquid

INDAG mixers are very well suited for mixing liquids. It is possible to mix two media, but a variety of liquids can also be mixed together. By liquids we mean pumpable media. Depending on the mixing task, the INDAG mixer types DLM/M, DLM/P, DLM/S and DLM/H are suitable for mixing liquids for confectionery.

Application examples Gentle Inline Mixer:

- Egg white + chocolate with butter

- Fondant + egg white foam

- Fondant and egg white foam + flavouring

- Ice cream + fruit preparation

Application examples Dynamic Inline Mixer:

- Candy paste (hard) + citric acid

- Fat-based cream filling + rum sultana paste

- Fat filling + milk chocolate, coffee paste

- Fat filling + milk chocolate, nut paste

- Fat filling + liqueur, syrup

- Fat filling + flavouring

- Fat filling + coffee paste

- Fat filling + nut pulp, coffee paste

- Fat filling and milk filling + additives

- Fondant + colour/flavour

- Fondant + flavour

- Fondant + additives

- Jelly + acid

- Melted sugar mass + chocolate fat mass, flavouring

- Caramel + Rework Caramel, Aroma

- Caramel + colour, flavour

- Couverture

- Milk filling + coffee paste

- Milk filling + flavour

- Chocolate + flavouring

- Chocolate + butterfat

- Chocolate + colour, flavour

- Chocolate and coffee paste + foamed fat filling

- Chocolate and nut paste + foamed fat filling

- Chocolate, couverture

- Chocolate paste

- Toffee + Rework Toffee, flavouring

- Toffee + 3 flavours

- Vanilla sauce + coconut oil

- Milk chocolate + coffee paste, nitrogen

- Milk chocolate + nut paste, nitrogen

- Broken wafer + Chocolate paste

- Wine gum + apple pectin

Application examples

Intensive Inline Mixer:

- Milk + fat

- Praline filling + nitrogen

- Syrup + foaming agent

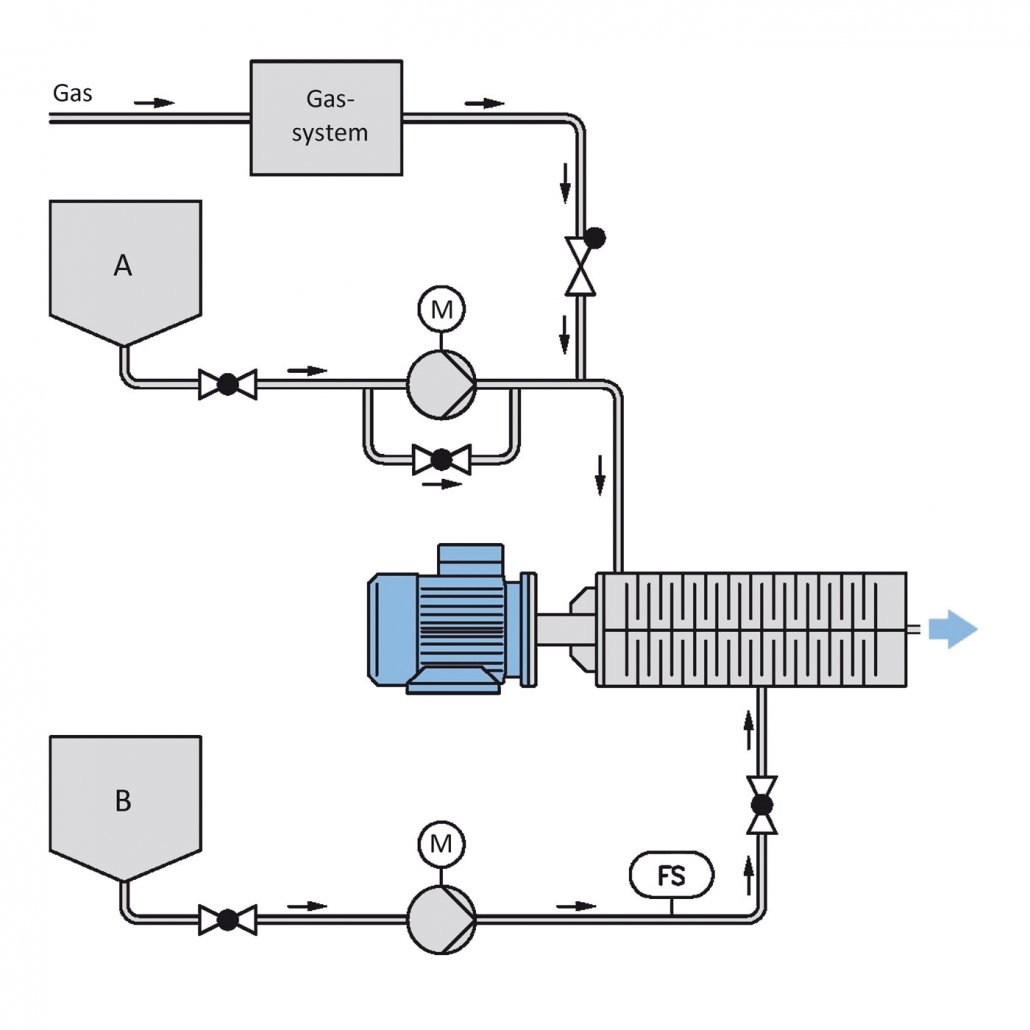

Liquid + Gas

High shear forces and relatively long residence times are required to produce foams or for continuous boiling with steam. The Intensive Inline Mixer type DLM/S is used for this task.

Application examples

Intensive Inline Mixer:

- Foaming up chocolate mousse

- Foaming chewing gum

- Foaming marshmallows

- Foaming chocolate

- Foaming toffee mass

- Foam wine gum

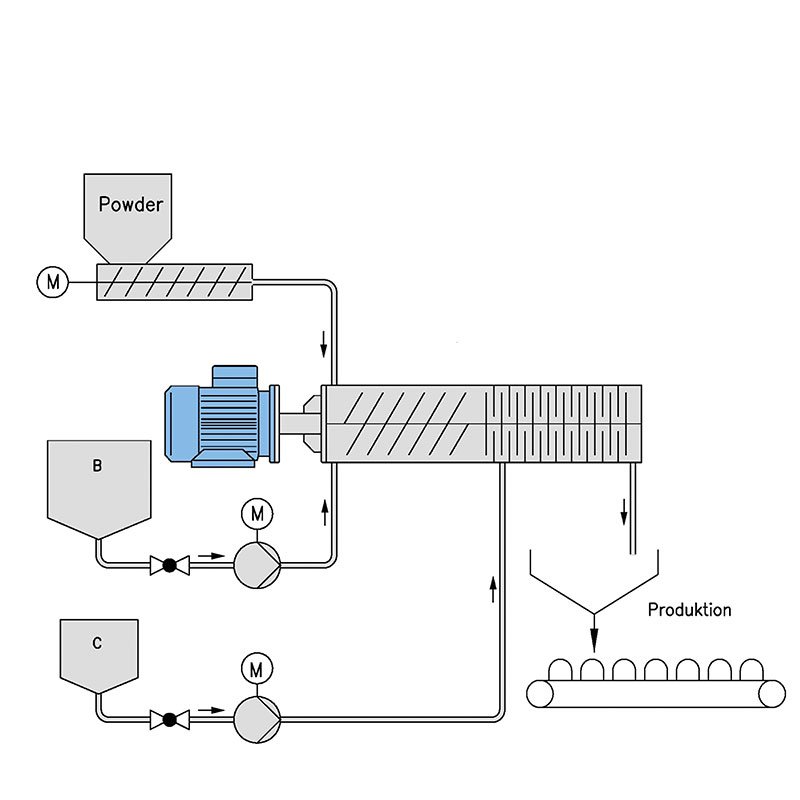

Liquid + Solids

The term 'solids' covers all non-pumpable media. These can be powders, granulates, or large particles. In order to continuously mix defined amounts of these into a liquid, we use our solid-liquid mixer type DLM / FS

Application examples Solid-Liquid Inline Mixer:

- Aerated fat mass + biscuit crumble

- Candy mass (140°C) + acid powder

- Ice cream + fruit, various solids

- Protein foam + cereals

- Peanut butter + cocoa powder

- Peanut butter + peanuts

- Peanut butter + chocolate or nut pieces

- Fat cream + crispies

- Fat mass + shredded coconut

- Jelly mass + cereal or powder

- Cocoa butter + chocolate powder

- Caramel + protein powder

- Nougat + chocolate or nut pieces

- Cream + chocolate chips

- Chocolate filling + powder

- Chocolate + almonds, nuts or cornflakes

- White chocolate + colour powder

- White chocolate + fruit powder

+

+

+

+

+

+

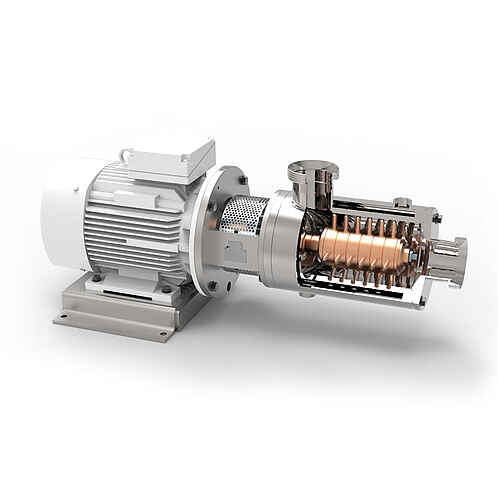

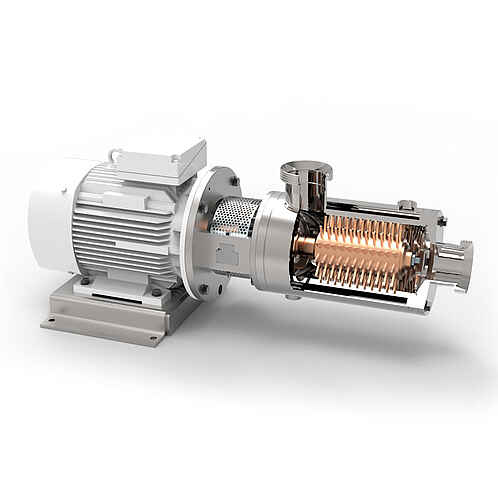

![INDAG DLM/FS - Solid-Liquid Inline Mixer [Translate to English:] INDAG DLM/FS - Fest-Flüssig Inline Mischer](/fileadmin/_processed_/f/e/csm_indag-dlm-fs-food-2021_aff8d6a87e.jpg)