DLM/H

Inline Homogenizer

High shear mixing for emulsifying and dispersing

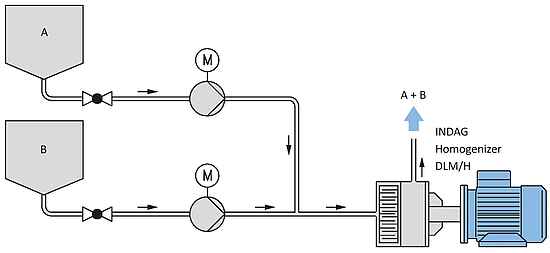

The INDAG inline homogenizer type DLM/H is used for effective dispersion (emulsification) and for producing a suspension of liquids and solids.

Advantages of DLM/H

- Efficient introduction of mixing energy

- Optimal completely heatable

- Hygienic construction

- Applicable at high pressures and high temperatures

- Variable mixing energy by speed change via frequency converter

- Very good self-cleaning during CIP-cleaning

Advantages of DLM/H

- Water + Oil

- Vegetable Oil + Phosphoric Acid

- Vegetable Oil + Citric Acid

- SLES Dilution

- Soybean/Rapeseed Oil + Phosphoric Acid

- Water + Flavorings, Altrodextrin (to create emulsion)

- Water + Emulsifier, Stabilizer

- Water + Wax

- Bentonite Suspension + Wastewater

- Biodiesel + Acid Process Water

- Biodiesel + Water

- CPO + Acid

- Miscella Degumming

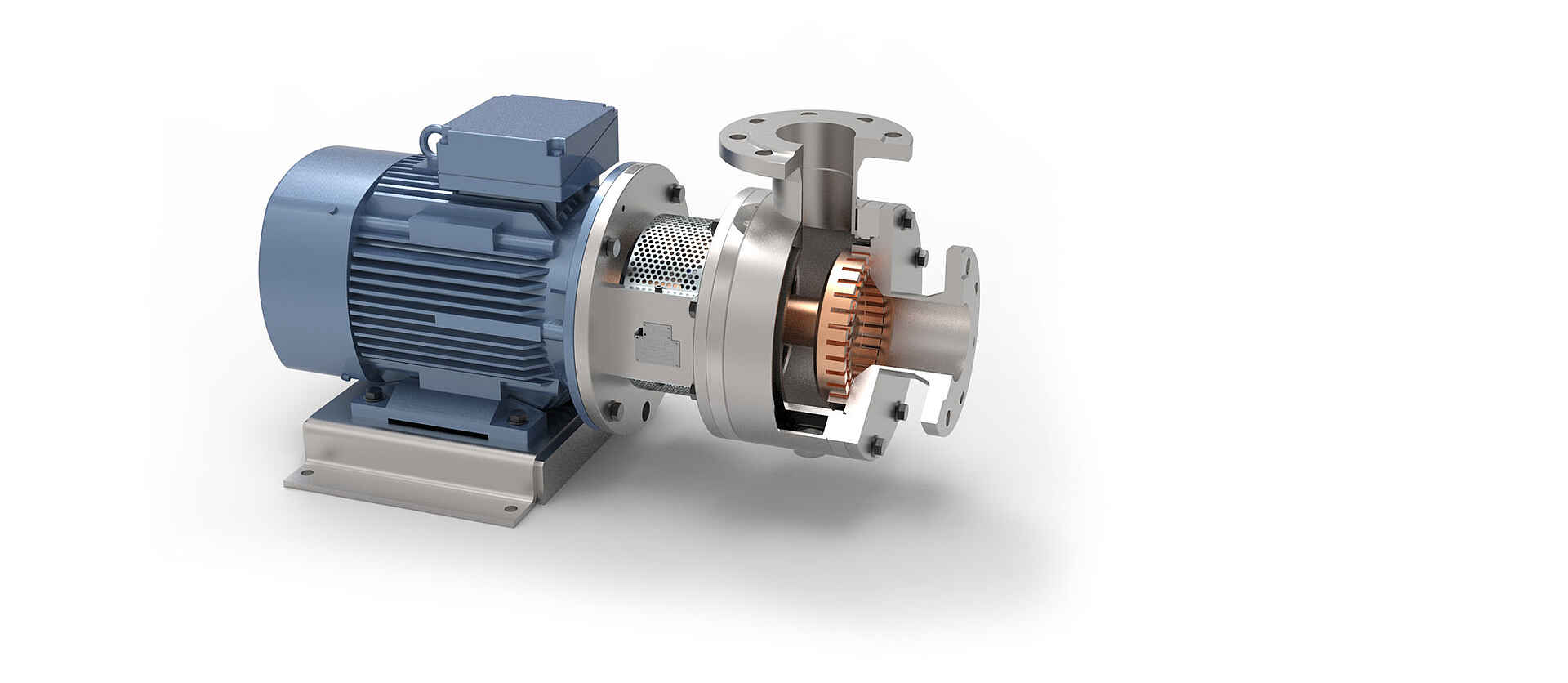

Technology of DLM/H

INDAG homogenizer type DLM/H consists of a rotor and stator equipped with axial positioned mixing/shearing elements. The stator can be designed to be cooled or heated. The DLM/H is offered in compact design (KB) and in bearing block design (LB). In the compact design, the rotor is mounted by the output shaft of the motor. In the bearing block design, the rotor is mounted by its own bearing block. With own bearing block, narrower shear gaps and thus a more intensive shear effect can be realized. Furthermore, this design is also suitable for mixing under high pressure or high temperature. The type of rotor seal is selected to suit each application. For the supply of the double acting mechanical seal INDAG offers the suitable barrier fluid system. INDAG mixers are designed likewise for explosive areas and substances (ATEX).

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 100 bar

Materials

1.4404 (AISI 316L), 1.4462 (AISI 318)

Seals

Single acting mechanical seal; double acting mechanical seal; stuffing box seal; visco seal

Connections

EN, DIN, ANSI flange and various others on request

Rotational speed

1,500 rpm to 6,000 rpm

Capacities

50 l/h to 120,000 l/h

Temperatures

0 °C to 300 °C

Viskosities

1 mPas to 500,000 mPas

Mixer sizes and capacities of DLM/H

| Type DLM/H | Unit | 2 | 3 | 4 | 5 |

| capacity* | l/h | 50-6.000 | 500-30.000 | 2.000-55.000 | 5.000-120.000 |

| connection | DN | 25-50 | 50-65 | 80-100 | 100-125 |

| optional | ASME | 1-2” | 2”-2½” | 3”-4” | 4”-5” |

| power* | kW | 2,2-4,0 | 4-11 | 11-22 | 37,5-90 |

| rotational speed* | 1/min | 1.000-6.000 | 1.000-5.000 | 1.000-3.600 | 1.000-3.600 |

| mixing stages compact version | DLM/H-202 KB | DLM/H-302 KB | DLM/H-402 KB | DLM/H-502 KB | |

| mixing stages bearing block version | DLM/H-303 LB | DLM/H-403 LB | DLM/H-503 LB |

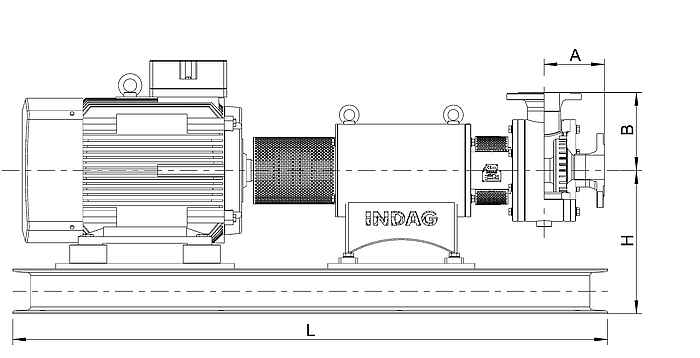

Dimension drawing of DLM/H with bearing block (LB)

| Type | Unit | A | B | H* | L* |

| DLM/H-302 LB | mm | 162 | 180 | 312 | 1500 |

| DLM/H-402 LB | mm | 174 | 210 | 385 | 1600 |

| DLM/H-502 LB | mm | 202 | 260 | 460 | 1800 |

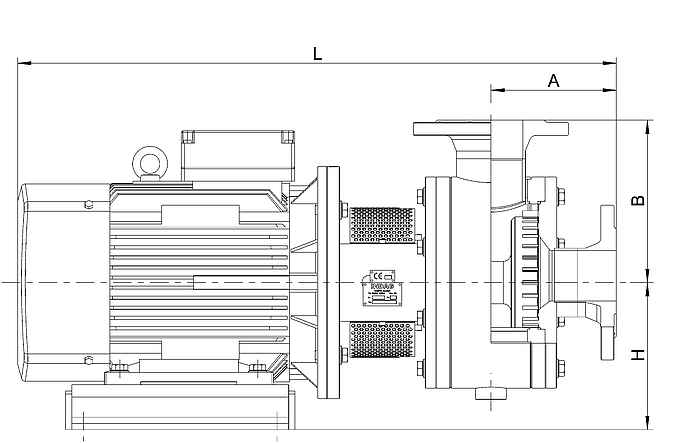

Dimension drawing of DLM/H compact version (KB)

| Type | Unit | A | B | H* | L* |

| DLM/H-202 KB | mm | 130 | 165 | 170 | 595 |

| DLM/H-302 KB | mm | 162 | 180 | 190 | 775 |

| DLM/H-402 KB | mm | 174 | 210 | 190 | 835 |

| DLM/H-502 KB | mm | 202 | 260 | 238 | 1010 |