Mixers for plastic

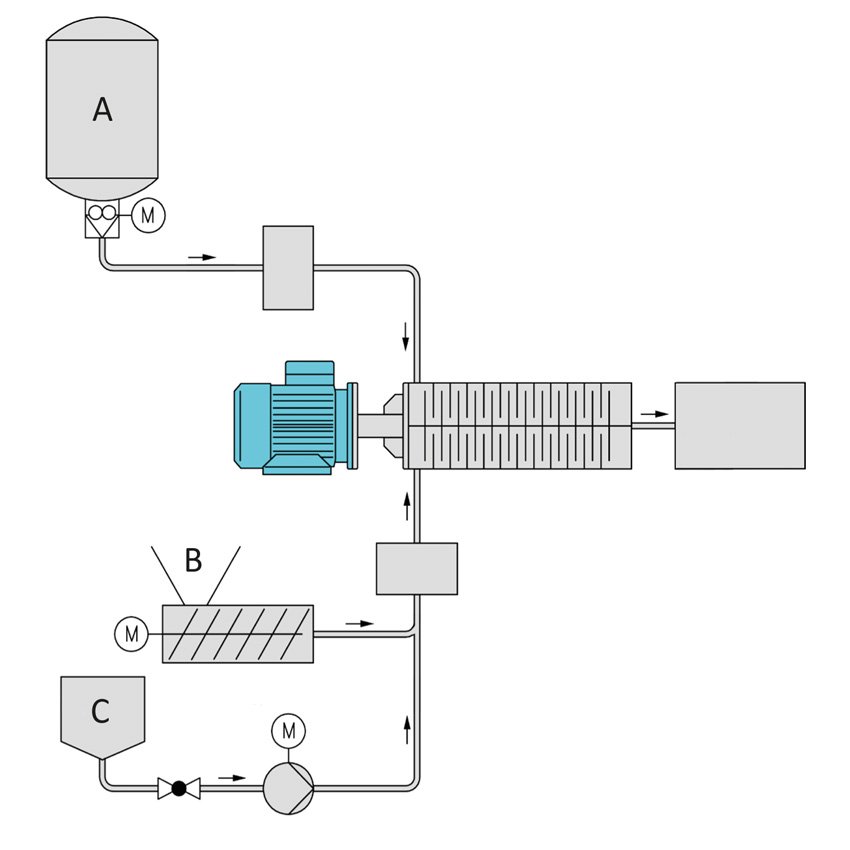

When mixing plastics, clean processing, suitable materials and an adapted mixing process are essential. INDAG dynamic inline mixers are compact and space-saving and fit perfectly into existing polymer lines. The dimensioning and design of the INDAG machine is flexible and can easily be adapted to existing lines. Lower speeds of the mixing elements ensure gentle polymer treatment. INDAG has cooperations with some German universities where research is carried out with INDAG mixers with different medium and high viscosity products. This enables us to continuously optimise our mixers.

Liquid + Liquid

INDAG mixers are very well suited for mixing liquids. It is possible to mix two media, but a variety of liquids can also be mixed together. By liquids we mean pumpable media. The INDAG mixer type DLM/S HP is suitable for mixing liquids for plastic products.

Application examples

High Pressure Inline Mixer:

- Caprolactam + stabiliser, TiO2 solution

- PET + phosporic acid

- Polybutadiene phthalate + additives

- Polybutene 1-polymer + Stabilizer (hexane)

- Polyester resin + Polyester resin

- Polymer melt + water

- Polyol + air

- Polyol + crosslinker

- Polyol + catalyst

- Polyuretan + isocyanate

- PVA + water

- PVC powder + dimethylformamide

- PVC powder + DMF

- TPU reaction

- Hot melt adhesives

- Polymer melt A + Polymer melt B

- Polyamide + wax, colour masterbatch

- PA 6.6 + wax, colour masterbatch

- PA 5.6 + wax, colour masterbatch

- ABS + wax

- PS + wax

- Polycarbonate + various additives

- Polyester + various additives

- PBAT + crosslinker

- PBS + wax, colour masterbatch

- PBT + wax, colour masterbatch