DLM/KS

Hydrolysis Inline Mixer

Efficient hydrolyzing of sewage sludge

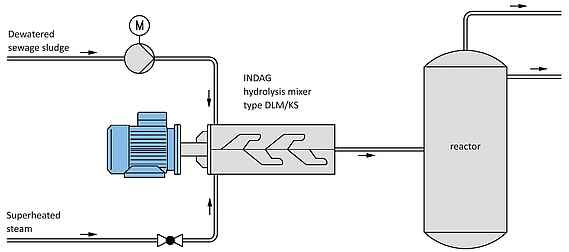

INDAG Hydrolysis Inline Mixer DLM/KS is used for efficient hydrolysis of dewatered sewage sludge. This target is reached by full condensation of pressure steam inside of dynamical mixer. Without intensive mixing of pressure steam into sewage sludge a lot of heat quantity is lost unused. Volume of downsteam reactor can be reduced. Hydrolyzed sewage sludge will be effectively dewatered in a second dewatering stage. Dry sub-stance (DS) content of dewatered sludge is increased. Transport costs of dewatered sewage sludge – i.e. to burn – is reduced.

Advantages of DLM/KS

- No pressure loss

- No blockage

- Entwining (clog) free

- Very homogeneous mixing result

- Mixing energy can be changed variable and adapted to product or capacity changes

- Higher DS-values of dewatered sewage sludge

- Considerable reduction of energy cost (pressure steam)

Technology of DLM/KS

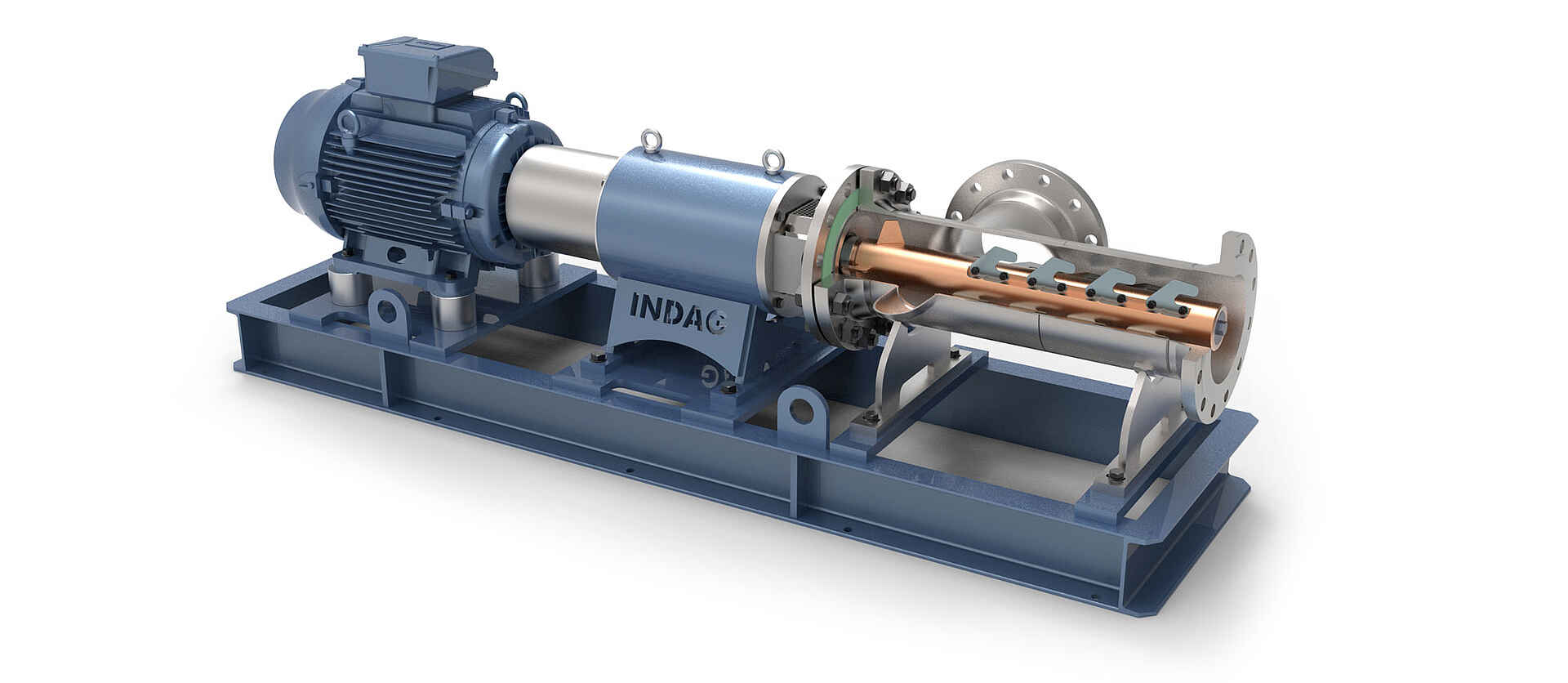

INDAG mixer type DLM/KS is equipped with flexible mixing elements on rotor. These mixing elements mix intensively and homogeneously pressure steam into sewage sludge. Rotor is supported by own bearing block. Bearing block is designed with strengthened bearings. Mixer DLM/KS is equipped with double acting mechanical seal. Mixer is designed for a maximal pressure of 18 bar and a maximal temperature of 207°C.

Positioning

horizontal or vertical position of mixer is possible

Pressure level

18 bar

Temperature

207°C

Materials

1.4301 (AISI 304), 1.4404 (AISI 316L)

Seals

Double acting mechanical seal

Connections

Flange DIN 2633, ANSI ‚ #300

Rotational speed

600 rpm to 1,700 rpm

Capacities

100 kg/h to 25,000 kg/h

Mixer sizes and capacities of DLM/KS

| Type | Unit | DLM/KS-1 | DLM/KS-2 | DLM/KS-3 | DLM/KS-4 | DLM/KS-5 | DLM/KS-6 |

| total capacity | kg/h | 100-500 | 250-2.000 | 500-4.000 | 2.000-8.000 | 4.000-15.000 | 6.000-25.000 |

| connections | DN | 80 | 100 | 150 | 200 | 250 | 300 |

| connections | inch | 4” | 4” | 6” | 8” | 10” | 12” |

| power | kW | 4 | 7.5 | 11 | 18.5 | 22 | 30 |

| rotational speed at 50 Hz | 1/min | 1.450 | 1.450 | 950 | 950 | 750 | 600 |

| rotational speed at 60 Hz | 1/min | 1.700 | 1.700 | 1.150 | 1.150 | 900 | |

| pressure | bar | 18 | 18 | 18 | 18 | 18 | 18 |

| pressure | psi | 260 | 260 | 260 | 260 | 260 | 260 |

| pressure vessel | no | no | no | (yes) | (yes) | (yes) | |

| temperature | °C | 207 | 207 | 207 | 207 | 207 | 207 |

| temperature | °F | 404 | 404 | 404 | 404 | 404 | 404 |

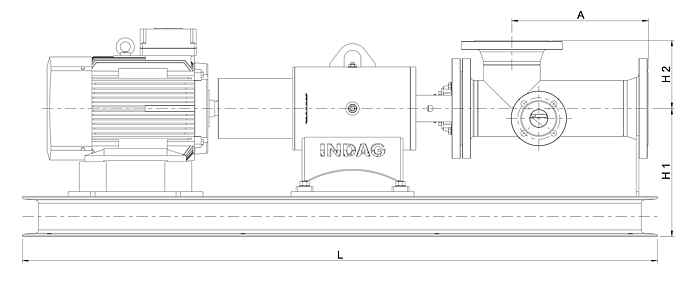

Dimension drawing of DLM/KS

| Type | Unit | L | H1 | A | H2 |

| DLM/KS-1 | mm | 1.470 | 152 | 295 | 149 |

| DLM/KS-2 | mm | 1.610 | 312 | 335 | 198 |

| DLM/KS-3 | mm | 1.885 | 385 | 405 | 225 |

| DLM/KS-4 | mm | 2.195 | 455 | 485 | 265 |

| DLM/KS-5 | mm | 2.490 | 530 | 575 | 320 |

| DLM/KS-6 | mm | 2.798 | 610 | 660 | 385 |