DLM/S

Intensive Inline Mixer

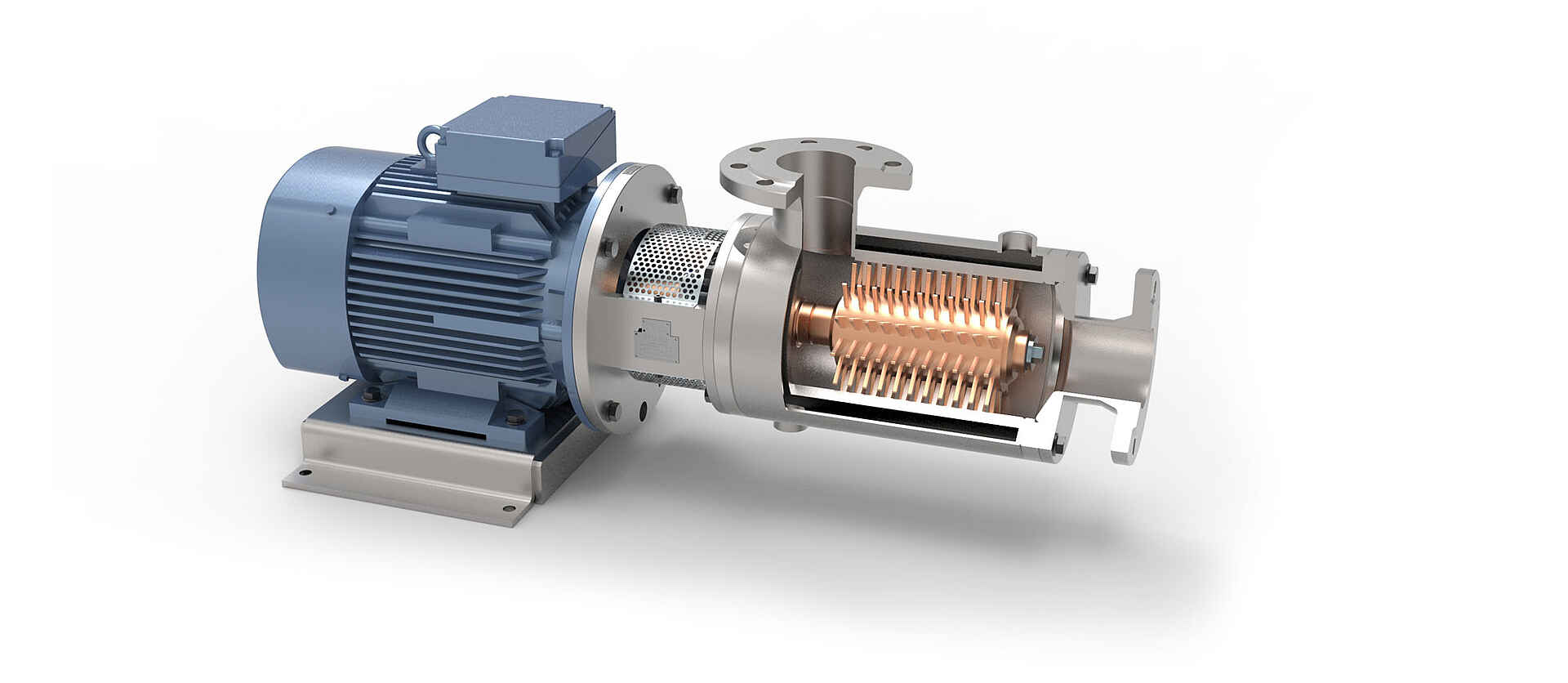

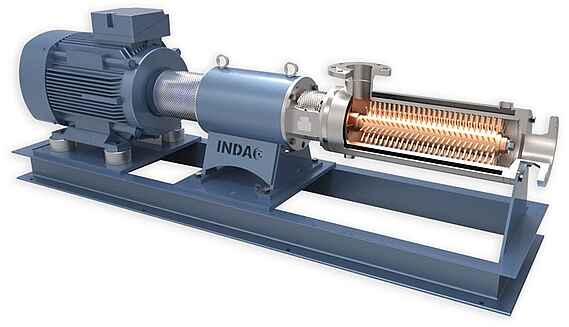

Intensive mixing with star mixing elements

for challenging mixing applications

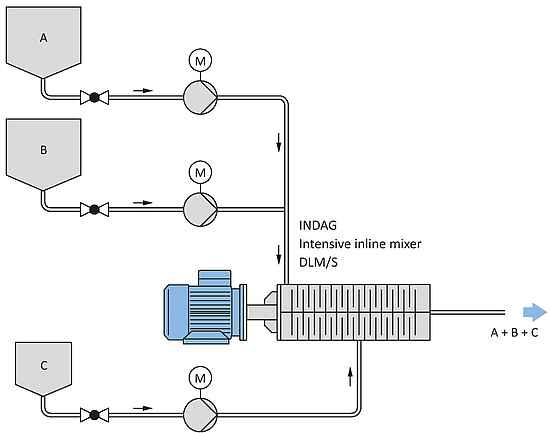

The INDAG Intensive Inline Mixer type DLM/S is used for the effective mixing, emulsifying, dispersing and foaming of various liquids and liquids with gases.

Advantages of DLM/S

- No pressure loss

- No blockage

- Very homogenous mixing result even for extreme concentration ratios

- Efficient introduction of mixing energy

- Variable mixing energy by speed change via frequency converter

- Applicable at high pressures and high temperatures

- Very good self-cleaning during CIP-cleaning

Application examples for the DLM/S

- Emulsions of silicone oil, water, and emulsifier

- Dispersions of polymer and steam

- Foams of latex, vulcanizing paste, and gelling agent

- Mixing of polymer melts (PET, PA, PE, PBT) and additives

- Mixing of vegetable oil, methanol, and methylate

Technology of DLM/S

INDAG mixer type DLM/S consists of star shape mixing elements on rotor and in stator (mixer casing). Star shape design is extremely robust to allow mixing of highly viscous products (70,000,000 mPas). Mixing energy is introduced efficiently into product. It is possible (as an option) to heat or cool rotor and stator. INDAG mixer DLM/S is designed in a modular way. A single acting mechanical seal can be changed to double acting mechanical seal without change of mixer. INDAG mixers are designed likewise for explosive range and products (ATEX).

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 100 bar, 160 bar

Materials

1.4301 (AISI 304), 1.4404 (AISI 316L), 1.4462 (AISI 318), PVDF, PTFE, Teflon 3.6 coated, Tantal coated

Seals

Single acting mechanical seal; double acting mechanical seal; stuffing box seal; magnetic coupling; visco seal

Connections

DIN, ANSI flange and various others on request

Rotational speed

100 rpm to 3,600 rpm

Capacities

50 l/h to 120,000 l/h

Temperatures

0 °C to 350 °C

Viskosities

1 mPas to 70,000,000 mPas

Mixer sizes and capacities of DLM/S

| Type DLM/S | Unit | 1 | 2 | 3 | 4 | 5 | 6 |

| capacity* | l/h | 100-2.000 | 200-5.000 | 500-10.000 | 1.000-20.000 | 3.000-60.000 | 6.000-120.000 |

| connection | DN | 40-80 | 50-100 | 65-150 | 80-200 | 100-250 | 125-300 |

| optional | ASME | 1,5”-3” | 2”-4” | 2,5”-6” | 3”3”-8” | 4”4”-10” | 5”5”-12” |

| power* | kW | 0,55-4 | 1,5-7,5 | 2,2-22 | 4-45 | 5,5-90 | 11-160 |

| rotational speed* | 1/min | 200-3.600 | 200-3.600 | 200-1.500 | 200-1.500 | 200-1.500 | 100-1.500 |

| mixing stages KB | DLM/S-105 KB | DLM/S-205 KB | DLM/S-305 KB | DLM/S-405 KB | DLM/S-505 KB | DLM/S-605 KB | |

| mixing stages LB | DLM/S-110 LB | DLM/S-215 LB | DLM/S-320 LB | DLM/S-420 LB | DLM/S-520 LB | DLM/S-620 LB |

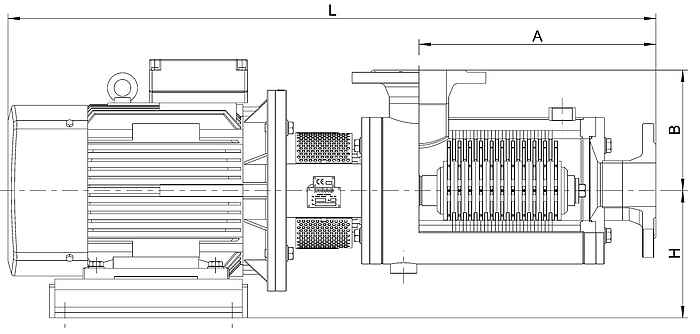

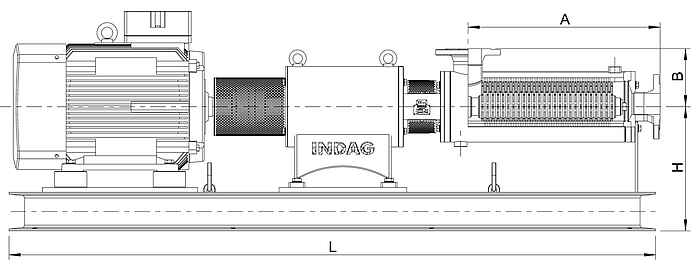

Dimension drawing of DLM/S with bearing block (LB)

| Type | Unit | A | B | H* | L* |

| DLM/S-110 LB | mm | 487 | 138 | 250 | 1300 |

| DLM/S-215 LB | mm | 508 | 165 | 312 | 1700 |

| DLM/S-320 LB | mm | 514 | 180 | 385 | 2000 |

| DLM/S-420 LB | mm | 547 | 210 | 460 | 2100 |

| DLM/S-520 LB | mm | 573 | 242 | 460 | 2200 |

Dimension drawing of DLM/S compact version (KB)

| Type | Unit | A | B | H* | L* |

| DLM/S-105 KB | mm | 327 | 138 | 148 | 855 |

| DLM/S-205 KB | mm | 348 | 165 | 148 | 799 |

| DLM/S-305 KB | mm | 354 | 180 | 190 | 968 |

| DLM/S-405 KB | mm | 387 | 210 | 190 | 1030 |

| DLM/S-505 KB | mm | 413 | 242 | 218 | 1092 |