DLM/P Dynamic Inline Mixer

Dynamic mixing with Pin mixing elements

for shear sensitive products

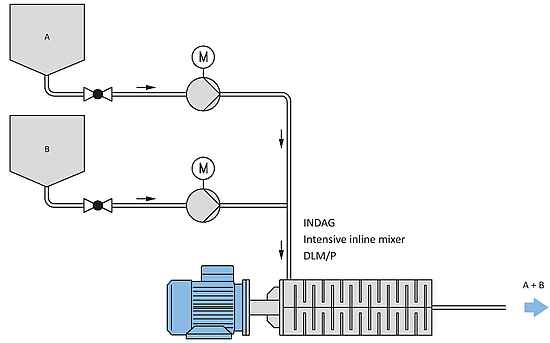

The INDAG Dynamic Inline Mixer Type DLM/P is used, among other things, for the homogeneous mixing of shear-sensitive liquids with additives. Additives can be mixed homogeneously in very small quantities of less than 0.01%. The shape of the mixing elements also reduces heat input into the product stream to a minimum. This means that temperature increases can be kept below 1°C. Temperature-sensitive products can thus be mixed gently and homogeneously. Alternatively, the parameters can also be selected so that heat is actively introduced into the product.

Advantages of DLM/P

- No pressure loss

- Very good homogeneous mixing result even when mixing in smallest quantities (0.01 %)

- Efficient introduction of mixing energy

- Variable mixing energy by speed change via frequency converter

- Temperature increase less than 1 °C

- Applicable at high pressures and high temperatures

- Very good self-cleaning during CIP-cleaning

Application examples for the DLM/P

- Emulsion + pearl phase

- Polyol + isocyanate + catalyst

- Adhesive + isocyanate

- TPU production

- TPU modification

- Detergents + additives

- Adhesives with colors

- Polymer mixtures

- Oxidation solution with oil solution = reverse emulsion

Technology of DLM/P

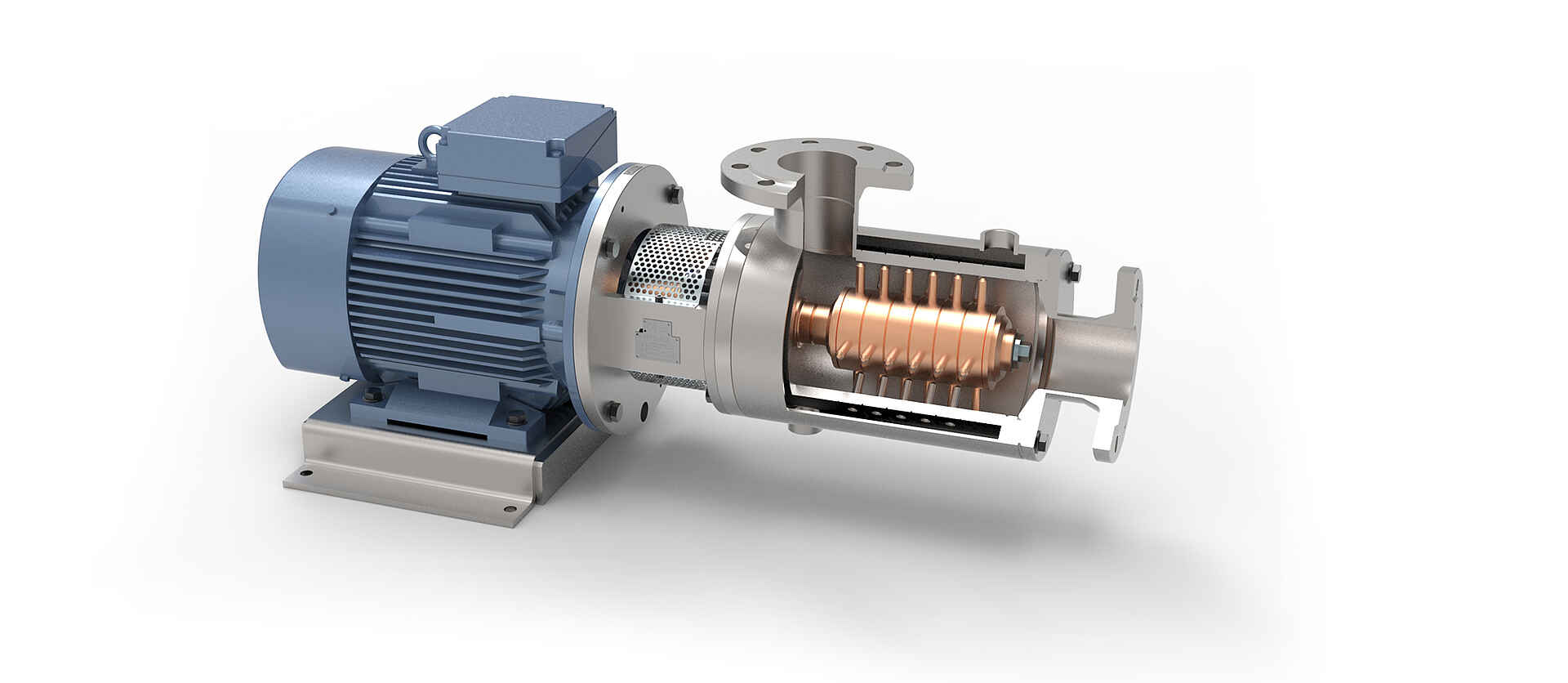

INDAG Dynamic Inline Mixer type DLM/P consists of round shape mixing elements on rotor and in stator (mixer casing). Round shape mixing elements are extremely robust to allow mixing of highly viscous products (> 10,000,000 mPas). Mixing energy is introduced efficiently into product. It is possible (as an option) to heat or cool rotor and stator. The DLM/P is offered in compact design (KB) and in bearing block design (LB). In the compact design, the rotor is mounted by the output shaft of the motor. In the bearing block design, the rotor is mounted by its own bearing block. With a separate bearing block, longer rotors and thus larger mixing volumes can be realized. Furthermore, this design is also suitable for mixing under high pressure or high temperature. The type of rotor seal is selected to suit each application. For the supply of the double acting mechanical seal INDAG offers the suitable barrier fluid system. INDAG mixers are designed likewise for explosive areas and substances (ATEX).

Positioning

horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar, 100 bar

Materials

1.4404 (AISI 316 L), 14462 (AISI 318), Teflon coated, Tantal coated

Seals

Single acting mechanical seal; double acting mechanical seal; stuffing box seal, visco seal

Connections

DIN, ANSI flange and various others on request

Rotational speed

100 rpm to 1,500 rpm

Capacities

50 l/h to 60,000 l/h

Temperatures

0 °C to 250 °C

Viskosities

1 mPas to 10,000,000 mPas

Mixer sizes and capacities of DLM/P

| Type DLM/P | Unit | 2 | 3 | 4 | 5 | 6 |

| capacity* | l/h | 50-800 | 300-3.000 | 500-10.000 | 1.000-20.000 | 3.000-60.000 |

| connection | DN | 50 | 65 | 80 | 100 | 125 |

| optional | ASME | 2” | 2,5” | 3” | 4” | 5” |

| power* | kW | 1,5-7,5 | 2,2-22 | 4-35 | 5,5-55 | 11-75 |

| rotational speed* | 1/min | 200-1.500 | 200-1.500 | 200-1.500 | 100-1.000 | 100-1.000 |

| mixing stages KB | 8 | DLM/P-208 KB | DLM/P-308 KB | DLM/P-408 KB | DLM/P-508 KB | DLM/P-608 KB |

| mixing stages LB | 15 | DLM/P-215 LB | DLM/P-320 LB | DLM/P-420 LB | DLM/P-520 LB | DLM/P-620 LB |

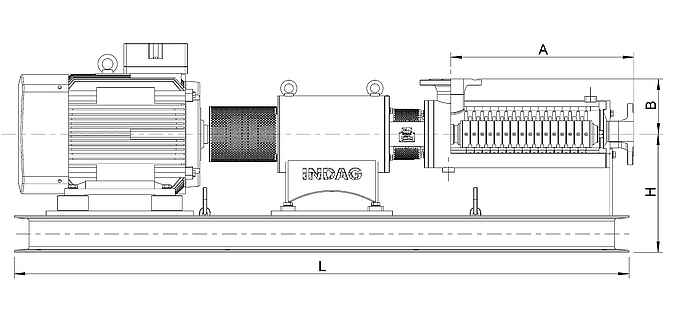

Dimension drawing of DLM/P with bearing block (LB)

| Type | Unit | A | B | H* | L* |

| DLM/P-220 LB | mm | 589 | 165 | 312 | 1700 |

| DLM/P-320 LB | mm | 595 | 180 | 385 | 2000 |

| DLM/P-420 LB | mm | 628 | 210 | 460 | 2200 |

| DLM/P-520 LB | mm | 654 | 242 | 460 | 2300 |

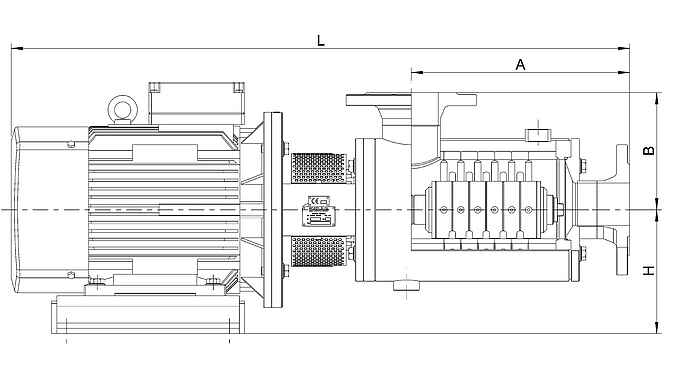

Dimension drawing of DLM/P compact version (KB)

| Type | Unit | A | B | H* | L* |

| DLM/P-208 KB | mm | 407 | 165 | 148 | 996 |

| DLM/P-308 KB | mm | 413 | 180 | 190 | 1027 |

| DLM/P-408 KB | mm | 446 | 210 | 190 | 1062 |

| DLM/P-508 KB | mm | 472 | 242 | 218 | 1104 |