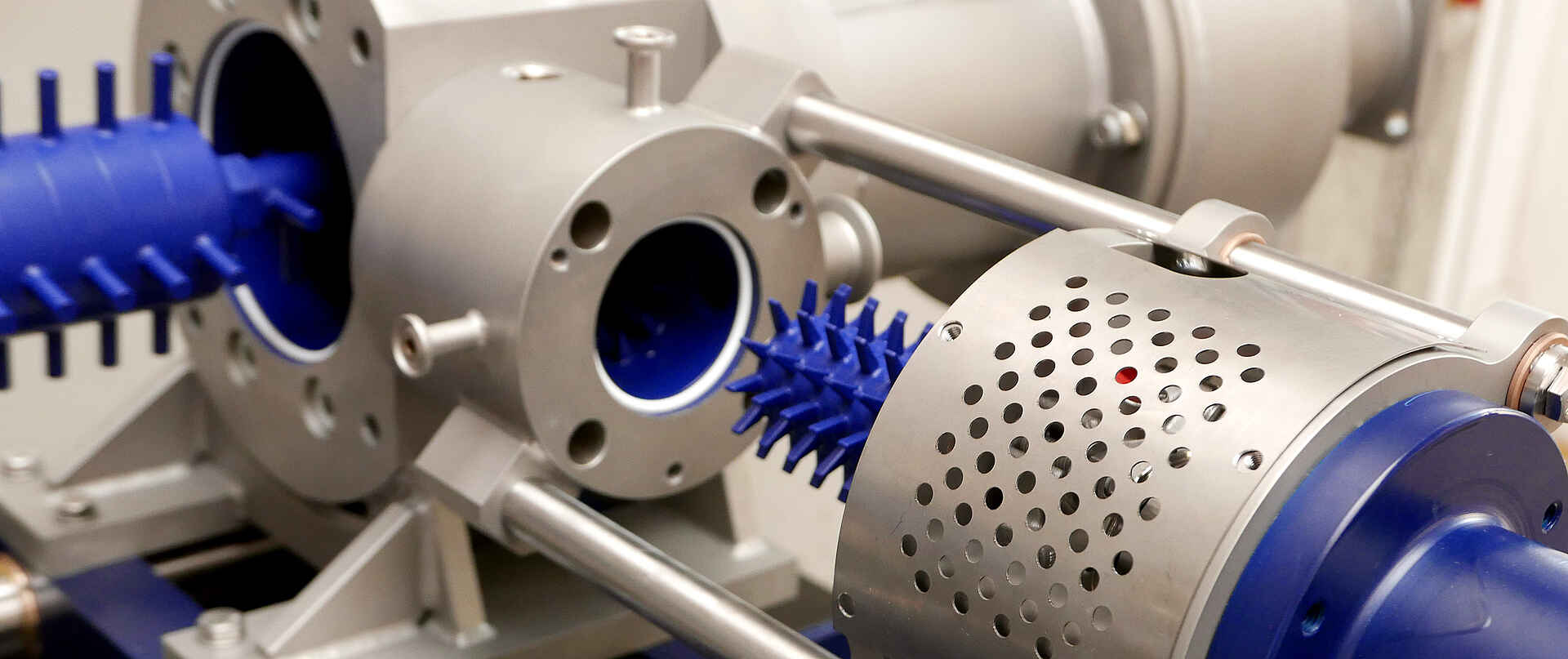

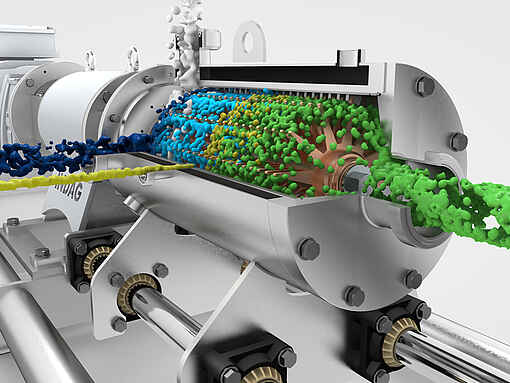

No matter if e.g. different liquids are mixed together, liquids with granulates or liquids with powders - an inline mixer dynamically mixes the ingredients directly in the mixer. As a result, continuous mixing ensures ongoing very good homogeneous mixing results – without individual batches and thus free of interruptions.

In direct comparison to batch mixing, continuous mixing is a compact, space-saving and very efficient solution.

The benefits at a glance:

- Continuous mixing guarantees continuously excellent homogeneous mixing results.

- Inlinemixers are extremely versatile, allowing the mixing of liquids with granules, powders and other liquids in almost every industry.

- Compared to a batch mixer, continuous mixers are a compact, space-saving solution.

- While only single batches can be mixed at a time in a batch mixer, continuous mixing is much more efficient in terms of capacity and time.

- Due to the small rotor diameters, continuous mixing is energy-saving.

- Thanks to CIP (Cleaning in Place), continuous mixers offer automated, sterile and fast self-cleaning.

- With continuous mixing, you always remain flexible during production – for example, product and capacity changes are possible at any time.

Overall, continuous mixing provides efficient, consistent results along the entire line.