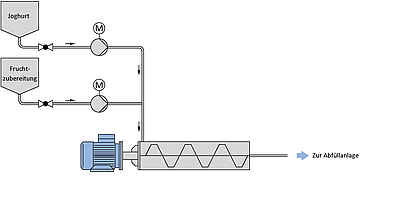

Process description of mixing yoghurt with INDAG mixers and accessories

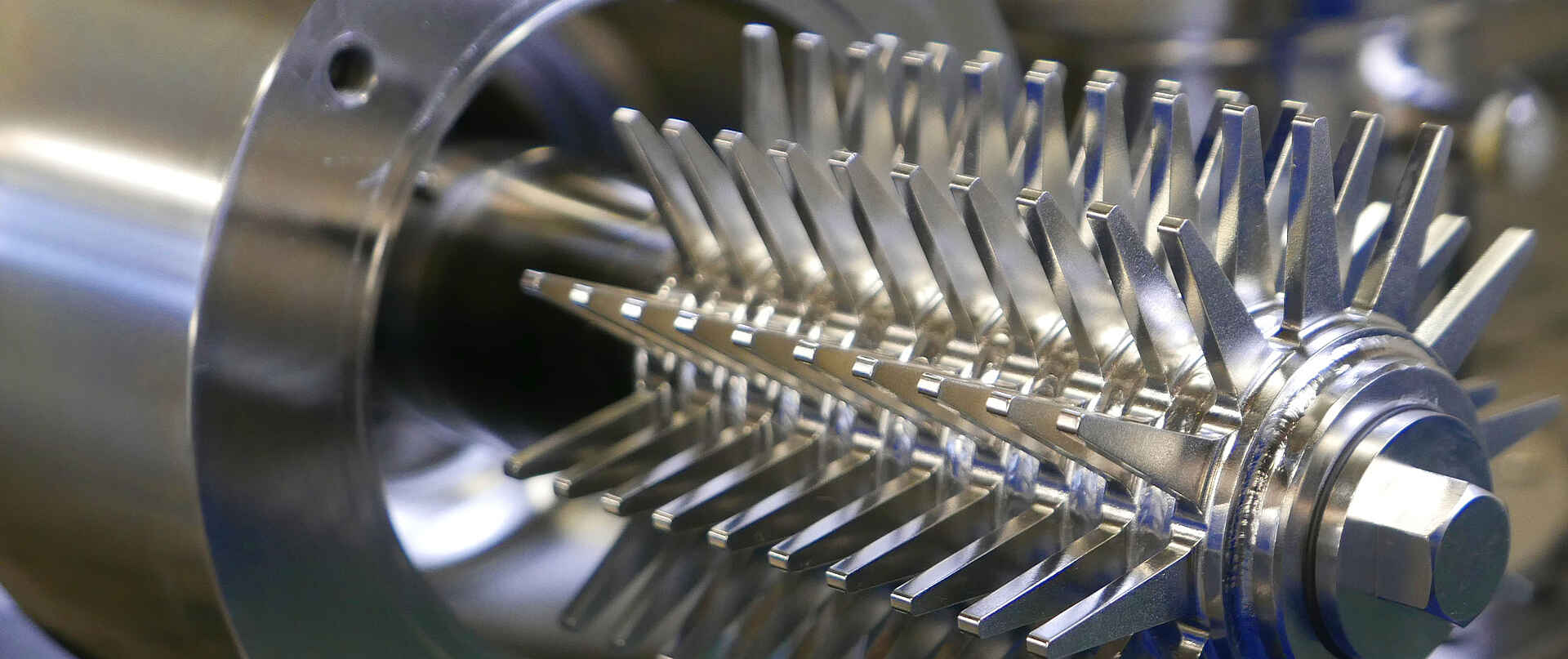

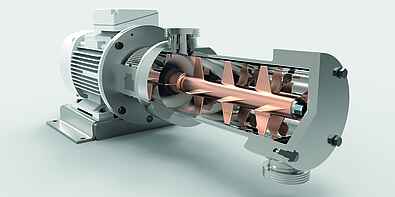

The pure yoghurt is pumped with a pump (often a rotary piston pump or screw pump) at approx. 4-12 °C through our mixer to the customer’s filling plant. The dynamic mixer allows any kind of fruit preparation to be mixed homogeneously into the yoghurt very effectively. Even fruit pieces of > 15 mm are mixed in gently without being destroyed. Also the structure of the yoghurt is not changed by the gentle mixer. This is usually done as close as possible to the filling line, since as little product as possible is discarded during fruit change. A maximum dosing accuracy is achieved with inductive flow meters. The dynamic mixers used are of course CIP and SIP cleanable.

Comparable application with a similar process and the same INDAG Gentle Inline Mischer

Mixing of Yoghurt or Curd or White cheese with fruit jam

Mixing of Yoghurt or Curd or White cheese with cream

Mixing of Yoghurt or Curd or White cheese with fruit concentrate

Mixing of Yoghurt or Curd or White cheese with fruit syrup

Advantages of continuous mixing with the dynamic INDAG mixer:

- Open dynamic seal area, easy to detect leakage;

- Very low volume in mixer saves product during CIP or SIP cleaning;

- Very efficient; perfect mixture within a few seconds;

- Minimized stress into product;

- Even large fruit particles don‘t get damaged.

- Available in aseptic execution for babyfood or pharmaceutical.

- The mixers are available with all common pipe connections, according to customers request.

- In case of order, customer receives detailed drawings in dwg, dxf or step file to prepare installation before the arrival of the machine.

- More than 60 years of experience in manufacturing dynamic inline mixers;

- Long list of worldwide partners withservice on side.

Here you can find more information about our Gentle Inline Mixer, Type DLM/M.