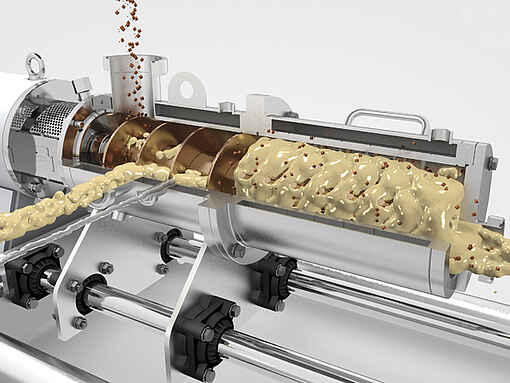

Process Description

The peanut butter is fed at 40-55°C by an external pump into the inline Solid-liquid mixer. It is coming from upstream shelling, roasting, grinding and blanching process. The solid ingredients are fed by a loss in weight feeder (dosing scale) into the INDAG continuous Solid-liquid mixer. There could be two or more solid streams at the same time. Typical solids are: Salt, cocoa powder, nut pieces, chocolate pieces, crunchy flakes and many more. There are almost limits in recipes. The rotating mixer is feeding the product by a helical screw and mixing by rotor and stator elements at the same time. Mixing procedure is very gentle. The peanut butter is very shear sensitive. Too much shear will separate the fat from the solid material. INDAG insure a very gentle inline mixing so temperature increase is below 1°C. The product leaves the mixer on face side. It is gently and homogeneously mixed and nearly pressureless. Rotor-stator clearances are designed according to the particles. This insures the perfect mixture for each application. The installation of the mixer is mostly direct in front of a filling line. We call it „end of pipe mixing“. If „end of pipe mixing“ is not applicable, a pump behind the mixer is needed to feed the product to next process step.

In case of manual cleaning, INDAG can offer “Easy clean” slides for mixer casing. This enables a very short and very easy manual cleaning procedure. Of course the mixer is as well CIP cleanable.

Production capacities vary from a few hundred kilogram per hour up to seven or more tons per hour.

Advantages that INDAG mixers offer for this mixing application:

- Highest flexibility for customers with changing recipes

- „End of pipe mixing“ minimize the cleaning effort while recipe exchange

- Compact and very efficient mixing head minimize wasted product during product exchange

- Temperature increase below 0.5°C while mixing

- Very gentle mixing. The structure of the peanut butter is not negatively influenced by the mixer.

- Closed hygienic design, easy to clean. Suitable for CIP cleaning

- Best possibility to add crunchy flakes and to keep them crunchy in the peanut butter

Comparable application with a similar process and the same mixer

- Tempered chocolate with nuts, dry fruits or chocolate pieces

- Cake or chocolate filling with nuts, dry fruits or chocolate pieces

- Marshmallows with nuts, dry fruits or chocolate pieces

- Ice cream with nuts, dry fruits or chocolate pieces

- Nougat with nuts, dry fruits or chocolate pieces

- Sugar-egg-foam with nuts, dry fruits or chocolate pieces

Here you can find more information about our solid-liquid inline mixer, type DLM/FS.