Process description

There are various ways to recycle plastic waste via a dynamic inline mixer. One possibility is to return the plastic as a melt to the reaction process. This can be a pure plastic, e.g. PET, but also mixtures of PET, PP, PA, etc. In this case, the plastic waste is fed to the mixer via an extruder. In the mixer, this melt is then intensively and very efficiently mixed into a liquid main stream. In the polymerisation process, the liquids are the monomer, ethylene glycol or, even further upstream oil (VGO) in the oil refinery process. Subsequently, in the reactor column, the added plastic, which has been dissolved in the meantime, is used again as a valuable material.

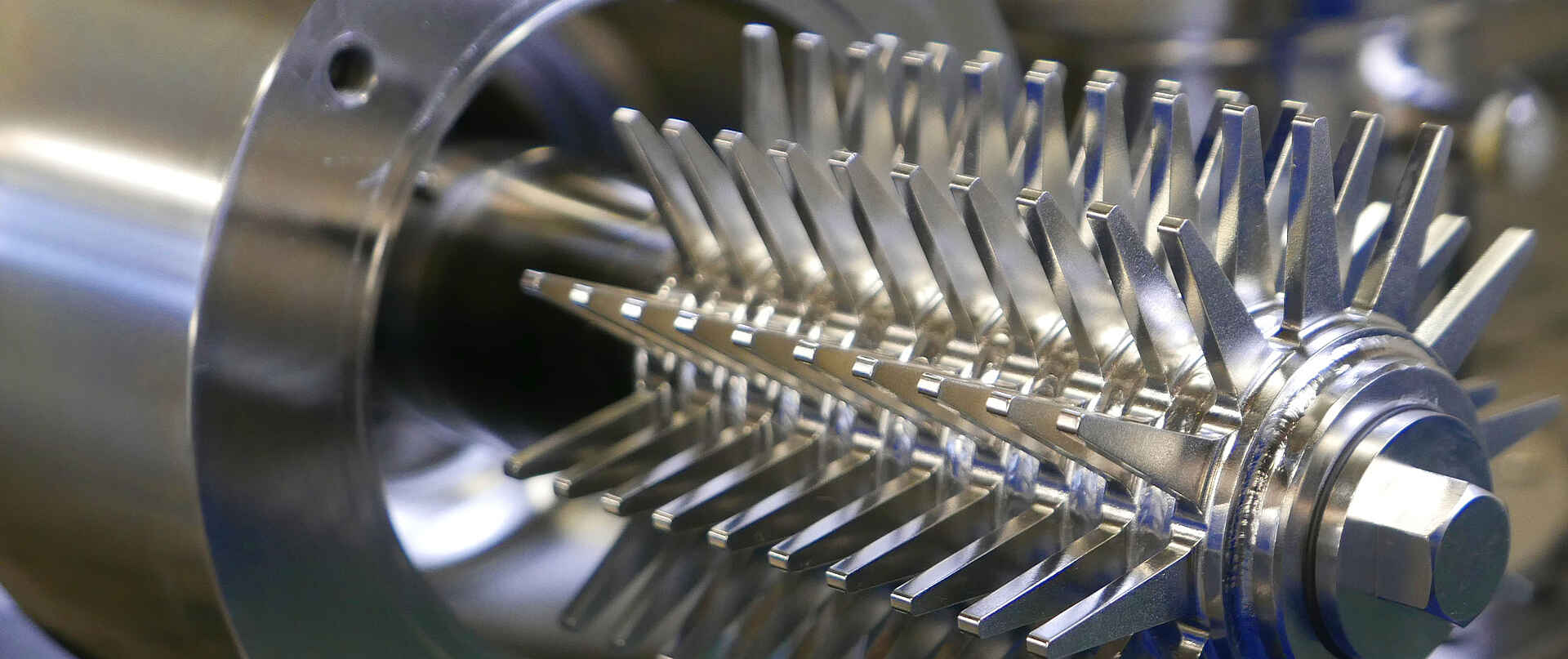

The INDAG Intensive Inline Mixer is suitable to withstand the high demands on temperature resistance, up to 420°C or also process pressures of up to 160 bar. Due to the large free cross-sections, the pressure loss inside the mixer is almost negligible. Furthermore, the large free cross-sections have the advantage of being able to take up and process large particles. Abrasive

media do not affect the mixer because of the wide clearances between rotor and stator. Should wear occur on the mixing elements after years, they can be quickly and easily replaced as spare parts.

Comparable applications with a similar processes and same mixer

- PET Gylcolisation

Advantages

- Acceleration of reaction times through very homogeneous mixing;

- Nearly every thermoplastic plastic material as well as plastic mixtures can be reintroduced into the production process.

- Very fine droplet sizes of the plastic melt improve the subsequent reaction process.

- No lump formation, which leads to problems in the downstream reactors;

- No clogging, no pressure loss in the mixer;

- Very energy-efficient due to optimal design of the drive power;

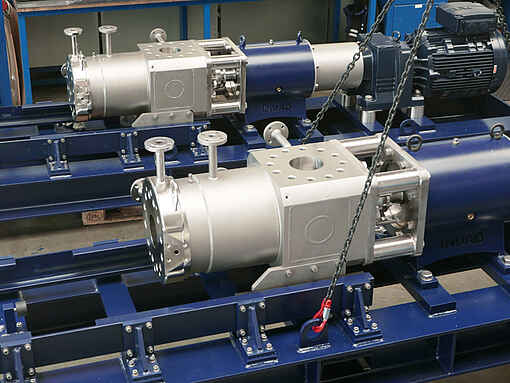

- Can be retrofitted in any existing process.

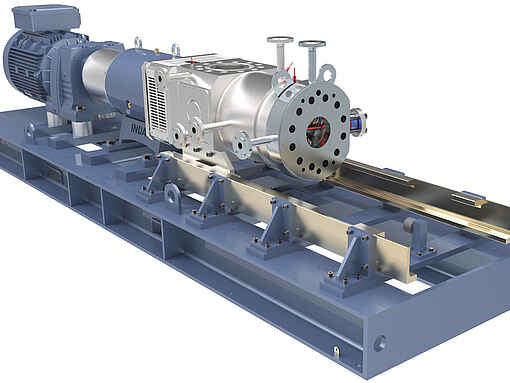

Here you can find more information about our Intensive Inline Mixer, type DLM/S.