The fruit gum mass is boiled homogeneously in a preparation container at approx. 85 - 110°C. The ingredients of the base mass are fruit juice or fruit puree as well as sugar and pectin. An external pump continuously feeds the heated mass into the INDAG Solid-liquid Inline Mixer DLM/FS.

The solids, such as citric acid powder, vitamin C, vitamin E or calcium, are fed gravimetrically or volumetrically into the inline mixer via a solid feeder. One or more solids can be dosed at the same time. As vitamins in particular are very temperature-sensitive, they should not be added in the cooker, but at the very end of the process, directly before filling/depositing. Other solids can be crispies or fibres, etc. Liquid additives such as food colourings or flavourings can also be dosed within the mixing zone.

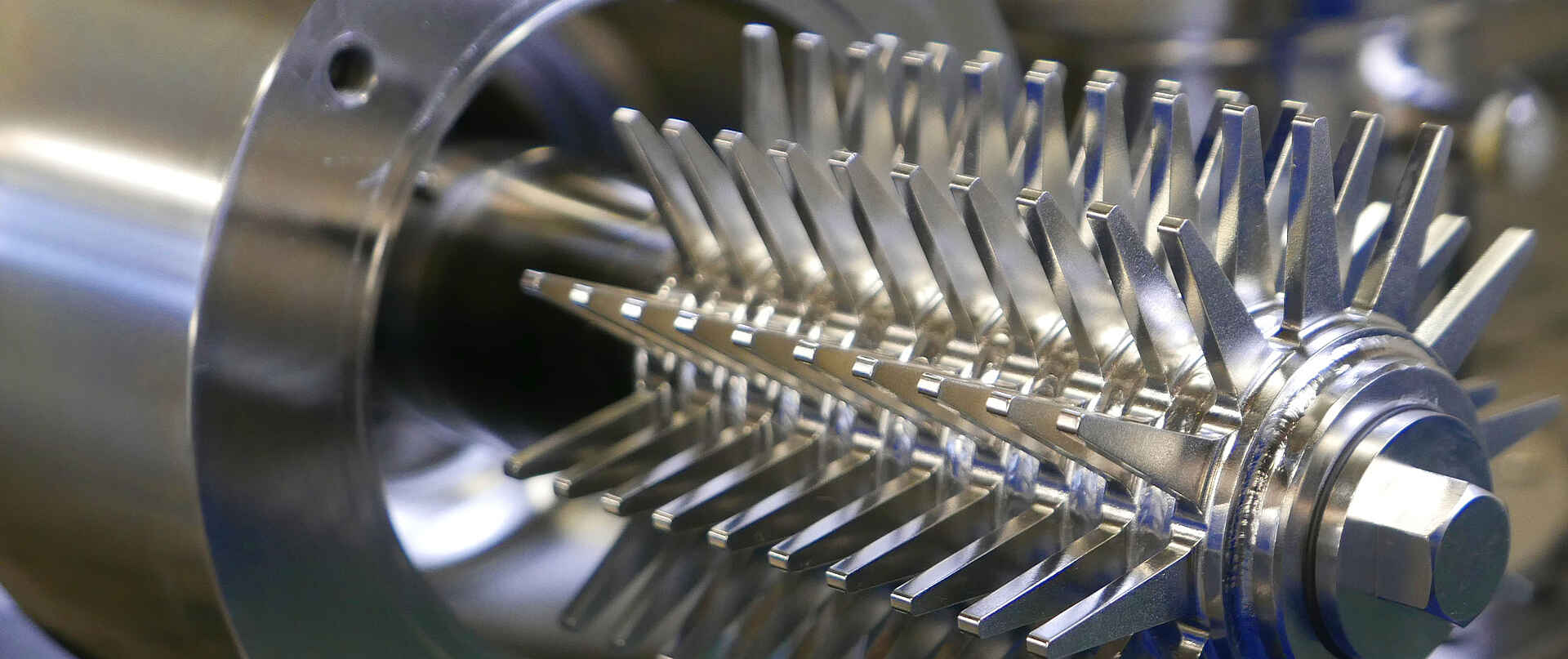

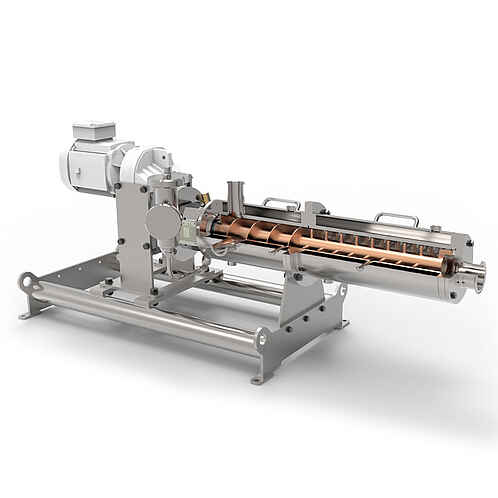

The rotating mixer conveys the products via a screw conveyor and at the same time ensures uniform mixing with its rotor and stator principle. Thanks to the correct selection of pin mixing elements, little shear energy is introduced into the product, the product is not destroyed and a minimum heat input of less than 1°C is guaranteed. The homogeneously mixed end product leaves the mixer at the front and is ready for filling.

The rotor-stator distances are designed according to the particle size. This ensures the perfect mixture for every application. The mixer is often installed directly in front of a filling line. We call this ‘end of pipe mixing’. If ‘end of pipe mixing’ is not applicable, a pump is required downstream of the mixer to feed the product to the next process step.

In the case of manual cleaning, an INDAG ‘Easy Clean’ slide can be installed for simplified and ergonomic opening of the mixer housing. This enables a very short and very simple manual cleaning process. Otherwise, the mixer is, like all our inline mixers, CIP-capable.

Production capacities vary from a few hundred kilograms per hour to seven or more tonnes per hour.

Advantages

- The activation of the pectin by means of citric acid takes place very homogeneously, without the formation of lumps.

- Maximum flexibility for products with changing recipes

- ‘End of pipe mixing’ minimises the cleaning effort when changing recipes.

- Vitamins retain their full function, as they are only exposed to the high temperature for a very short time.

- Compact and very efficient mixing head minimises product losses during product changes.

- Even very large quantities of > 30 % protein or calcium can be mixed in homogeneously.

- Temperature increase of less than 1°C during mixing

- Very gentle mixing: The structure of the jelly mass is not negatively affected by the mixer.

- Closed hygienic design, easy to clean, suitable for CIP cleaning

Comparable applications with a similar process and the same mixer

- Flavouring caramel masses

- Hard candies with citric acid powder, colourings and flavourings

Find the INDAG Solid-Liquid Inline Mixer Type DLM/FS here.