The pumpable basic ingredients, such as fish meat or sauces, are fed into the feeding zone of the Solid-Liquid Inline Mixer DLM/FS via external pumps. The individually adjustable flow rate is controlled automatically and very precisely via flow meters (provided by the customer), depending on the programmed recipe.

A gravimetric solid dosing unit is used to precisely dose the solid components as a pre-mix of solids or as individual components in the correct ratio to the liquid. Dosing screws are generally used for solids. For soft or even cooked solids, belt weighers are used, which dose particularly gently via a conveyor belt. Any powder dosing, e. g. of vitamins, calcium or proteins, is carried out using very precise twin screw feeders, which are precisely controlled by special electronic load cells underneath the hopper.

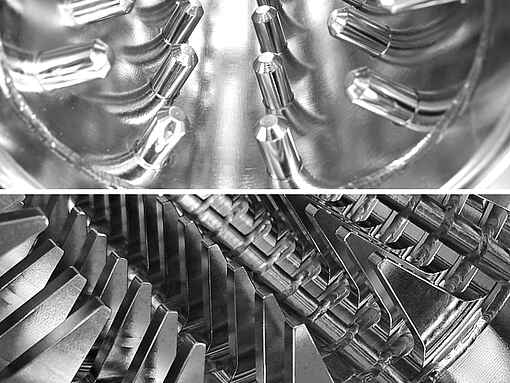

After the conveying zone, the mix automatically enters the mixing section of the mixer. Of course, liquid flavourings, vitamins or preservatives such as ascorbic acid can also be added to the mixing section at the same time, e.g. using diaphragm dosing pumps.

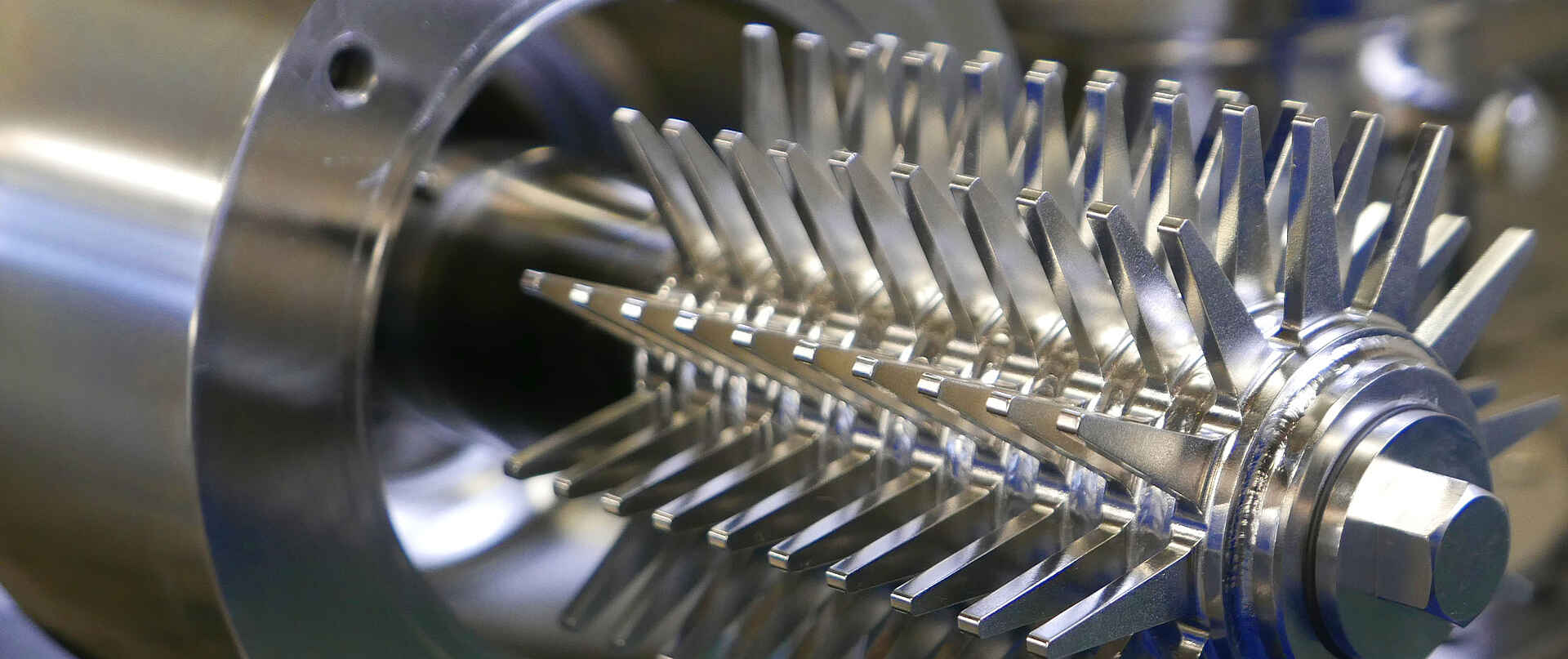

The mixers fulfil the highest industry standards and have very high quality components and a double-acting mechanical seal with a very long service life. All mixers for pet food are subject to the highest hygiene standards and are supplied with corresponding FDA or EC 1935 standards.

Advantages

- Significant reduction in mixing time compared to conventional processes, which enables faster and and higher yield production 24/7.

- The short and very gentle mixing process means that even very sensitive media, such as cooked vegetables, retain their shape and structure.

- Various mixing elements, such as paddle, PIN or star-shaped mixing elements are available, depending on whether it is fibrous or coarse chunky pet food that is to be either preserved or chopped.

- Homogeneous mixing result even when mixing in small quantities in powder form (0.1 %).

- Compared to mixing processes in batch operation, less energy is required and therefore the use of our mixer contributes to reducing the CO2 budget.

- Temperature increase of less than 1°C

- Suitable for CIP cleaning

- Execution with ‘Easy-clean’ slide for quick and safe opening of the DLM/FS, eliminating the need for lifting equipment on site.

Comparable applications with a similar process and the same mixer

- Salads as a spread, e. g. egg salad or pollock salad

- Mashed potatoes with starch, oil and spices