Whether dark, white or milk chocolate

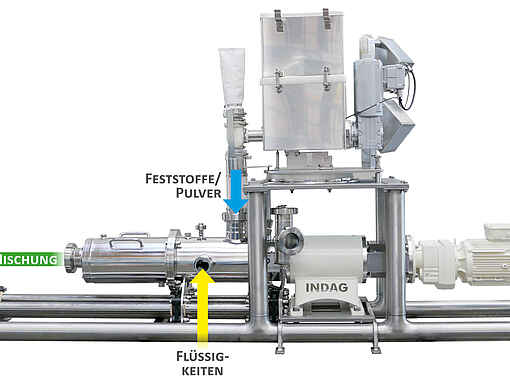

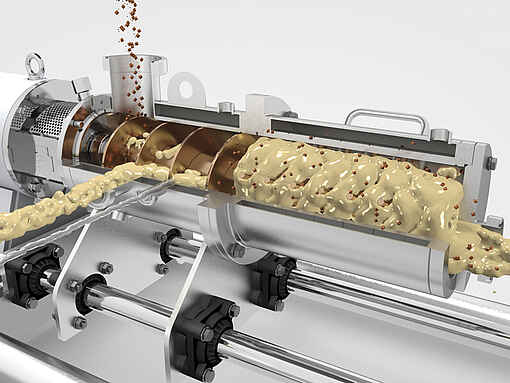

The already tempered chocolate comes directly from the tempering machine. Through a weight loss feeder come the solid components, which are very precisely dosed in relation to the chocolate flow. Solid ingredients can be, for example, puffed rice, nuts, raisins, fruit powder, spices such as chili, or any other solid ingredient. Of course, with membrane dosing pumps, liquid flavour or liquid colour could be added simultaneously.

The trick is to mix "End-of-pipe"

All ingredients are mixed "End-of-pipe", which means just before filling. On the one hand, this allows for a very flexible and fast product changeover without discarding a lot of valuable product. More importantly, unlike mixing in the temper, this and all the units afterwards, such as pumps, do not need to be cleaned when changing the additives. This becomes most important in case of including allergens, such as nuts.

Minimum temperatures for maximum homogeneous mixing results

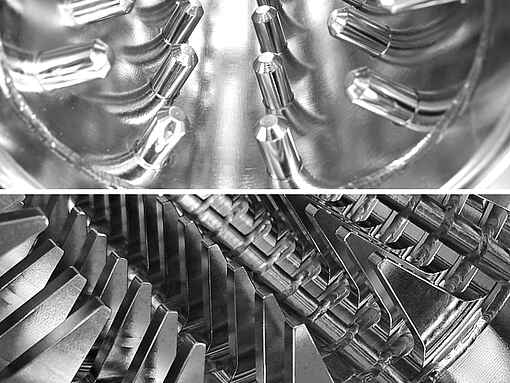

The INDAG Solid Liquid Mixer DLM/FS mixer for challenging but very sensitive mixing tasks, is ideal to provide an absolutely homogeneous mixture with minimum temperature input. The temperature rise during mixing is less than 0.5°C. What makes the continuous mixing technology so special: the possibility to mix almost all ingredients at the same time – regardless of the quantities. And it doesn't matter whether the ingredients are solid or liquid and whether they are large particles or fine powders. The result is always homogeneous. And all this is made possible by just one machine. All mixers in this branch are double jacketed to heat up the mixer before system start. Mixers come in hygienic design and are equipped with a solid shaft seal with long lifetime.

Advantages of Solid-Liquid Inline Mixer, Typ DLM/FS

- Highest flexibility for customer in changing recipes

- “End-of-pipe mixing” enables customer to renounce on temper cleaning

- Best distribution of very minor amounts of concentrated flavours and colours

- Temperature increase below 0.5°C while mixing

- Hygienic design, easy to clean, suitable for CIP self-cleaning

- Mixing of allergens in the very end of the process

Comparable application with similar process and same mixer:

- Tempered Nougat + Various Ingredients

- Marshmallows with Nuts, Dry Fruits or Chocolate Pieces

- Ice Cream with Nuts, Dry Fruits or Chocolate Pieces

- Nougat with Nuts, Dry Fruits or Chocolate Pieces

- Sugar-Egg-Foam with Nuts, Dry Fruits or Chocolate Pieces

- Peanut Butter with Nuts, Dry Fruits or Chocolate Pieces

Here you can find more information about our solid-liquid inline mixer, type DLM/FS.